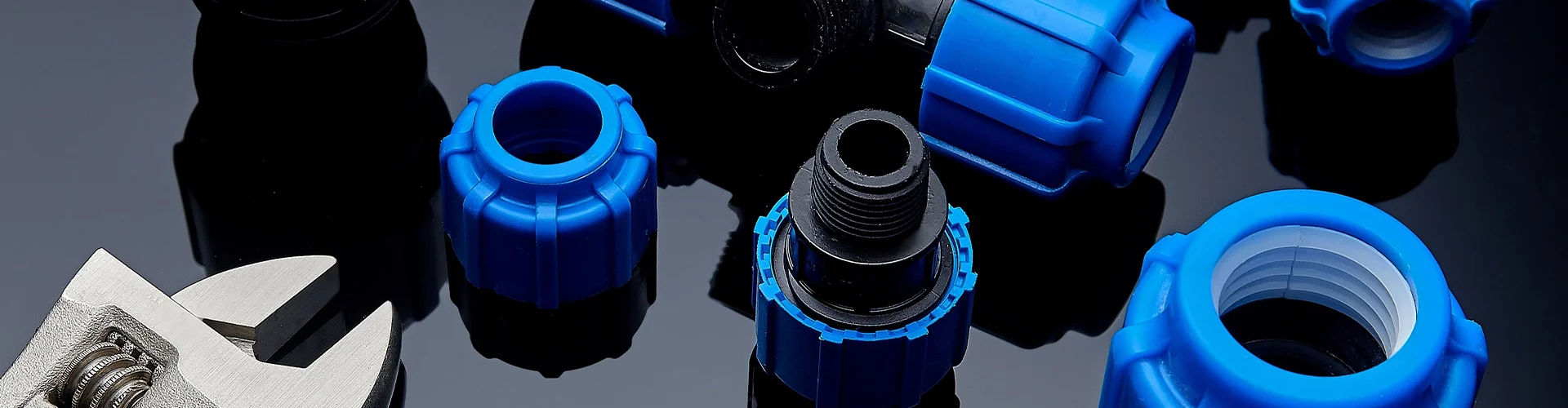

The HDPE Compression Coupling is an essential straight pipe connector designed to join two sections of high-density polyethylene (HDPE) or polyethylene (PE) pipe in a reliable, leak-free manner. Also known as an equal socket or straight coupler, this fitting creates a permanent yet demountable connection without requiring heat fusion equipment, making it indispensable for field repairs, system extensions, and temporary installations.

SIFFO's HDPE compression pipe joiner delivers exceptional durability across demanding environments. The precision-engineered push-fit mechanism with NBR sealing technology ensures rapid assembly while maintaining pressure ratings up to PN16 (16 bar) for sizes 20-63mm. Whether used in agricultural irrigation mains, municipal water distribution, or industrial fluid handling, this HDPE coupling provides the most cost-effective method for extending or repairing PE pipeline systems.

Key Features & Benefits

Equal Connection: Maintains identical internal diameter throughout the coupling, ensuring zero flow restriction and minimal pressure loss

Rapid Push-Fit Assembly: Complete pipe connection in under 60 seconds without specialized tools, welding machines, or skilled labor

Dual-Seal Technology: Primary NBR O-ring seal plus mechanical clinching ring provides redundant leak protection under dynamic pressure conditions

Universal Pipe Compatibility: Fits all standard HDPE/PE pipes conforming to ISO 4427, DIN 8074, EN 12201, and AS/NZS 4130

Pressure-Rated Performance: PN16 rating (20-63mm) and PN10 rating (75-110mm) suitable for high-pressure water distribution

Demountable & Reusable: Connection can be disassembled for system modification, pipe relocation, or maintenance without component damage

HDPE Compression Coupling Applications

Pipeline Repair & Maintenance

Fastest method for repairing burst pipes or damaged sections. Cut out defective portion and bridge with coupling—no system shutdown required for fusion equipment setup.

Irrigation System Extension

Extend existing HDPE irrigation lines to new field zones. Ideal for seasonal agricultural layouts requiring frequent system reconfiguration.

Municipal Water Infrastructure

Join PE100 water mains in urban distribution networks. Meets potable water standards with NSF/WRAS certified materials.

Temporary Bypass Lines

Construction site dewatering, event water supply, or emergency distribution. Quick assembly and disassembly for rental equipment applications.

Industrial Process Piping

Chemical transfer lines where welding is prohibited due to explosion risk or material degradation concerns.

Installation Instructions

Step 1: Pipe Preparation

Cut HDPE pipe square using a pipe cutter or fine-tooth saw. Remove all burrs and chamfer pipe end to 15° angle (approximately 1-2mm bevel) to allow smooth entry past O-ring seal without damage. Clean pipe end to remove dirt, grease, or moisture.

Step 2: Fitting Preparation

Loosen all three compression caps by unscrewing 3-4 turns counter-clockwise. Do not fully remove caps or dislodge internal components (clinching ring, bush, O-ring). Ensure O-rings are properly seated in grooves.

Step 3: Pipe Insertion

Firmly push prepared pipe ends into each port of the tee body until they contact the internal pipe stop. Visual confirmation through inspection holes (if equipped) or depth marking on pipe ensures full insertion depth critical for seal integrity.

Step 4: Compression Tightening

For DN20-32mm: Hand-tighten compression caps firmly until resistance increases significantly.

For DN40-63mm: Hand-tighten plus 1/4 turn with strap wrench.

For DN75-110mm: Hand-tighten plus 1/2 turn with appropriate wrench. Do not over-torque.

Step 5: Pressure Testing

Allow minimum 30 minutes for O-ring compression set before pressure testing. Gradually pressurize system to operating pressure and inspect all three ports for leakage. System ready for service upon successful test.

Quality Assurance & Certifications

ISO 9001:2015

Quality management system certification ensuring consistent manufacturing standards and traceability.

ISO 4427 Compliance

Meets international standards for PE piping systems in water supply, ensuring material compatibility.

EN 12201 Certified

European standard compliance for plastic piping systems in water supply, including pressure testing protocols.

Frequently Asked Questions

What is the difference between HDPE compression fittings and butt fusion fittings?

HDPE compression fittings use mechanical tightening to create a seal, requiring no heat or electricity—ideal for quick repairs and temporary installations. Butt fusion fittings require specialized welding equipment to melt and fuse pipe ends, creating a permanent, monolithic joint. Compression fittings are reusable; butt fusion joints are permanent.

Can HDPE compression elbows be used for gas applications?

These specific PP compression fittings are rated for water and compressed air (PN16/PN10). For gas applications, specialized gas-rated compression fittings or electrofusion fittings meeting EN 1555 standards are required. Always verify local regulations before gas installation.

How do I prevent leaks with compression fittings?

Ensure pipe ends are cut square and deburred, insert pipe fully to the internal stopper, and tighten according to size guidelines (hand-tight for ≤32mm, wrench-assisted for ≥40mm). Avoid over-tightening, which can damage the O-ring seal.

Technical Specifications

| Product Name | HDPE Compression Coupling |

| Size Range | 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, 75mm, 90mm, 110mm |

| Pressure Rating | PN16 (20-63mm) / PN10 (75-110mm) at 20°C |

| Material | PE100 |

| Color | Black body with Blue compression cap (custom colors available) |

| Connection Type | Mechanical Compression with NBR Rubber O-Ring Seal |

| Component Structure | Cap,Clinching Ring,Blocking Bush,O-Ring,Body |

| Standards | ISO 4427, EN12201 (Threads) |

| Temperature Range | -20°C to +60°C (water applications) |