The HDPE Buttfusion fittings developed and produced by SIFFO have excellent strength and wear resistance. They are specially designed for turning of pipeline systems to ensure smooth fluid delivery and reduce pressure loss. The product has excellent chemical corrosion resistance, high impact resistance and long life, and is suitable for a variety of application scenarios such as water supply and drainage, gas, chemical industry, and mining.

Product Features

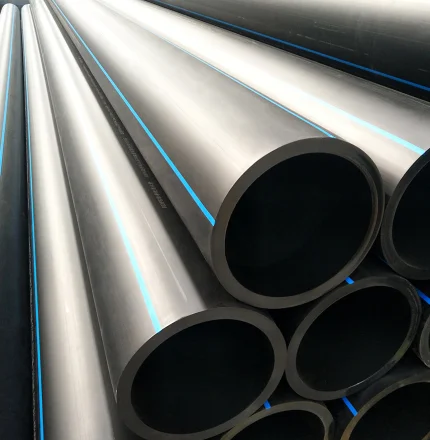

✅ High strength and pressure resistance: Using PE80/PE100 grade raw materials, it has strong pressure bearing capacity and is suitable for pipeline systems of different pressure levels.

✅ Excellent corrosion resistance: It can resist the erosion of acids, alkalis, salts and various chemical media, and is suitable for chemical and sewage treatment environments.

✅ Flexible and earthquake-resistant: HDPE material has good flexibility, can adapt to foundation settlement and earthquake effects, and reduce the risk of pipeline rupture.

✅ Low flow resistance design: Smooth inner wall reduces fluid resistance and improves delivery efficiency.

✅ Reliable hot-melt connection: Electric fusion or hot-melt butt connection is adopted to ensure seamless and leak-free interfaces.

✅ Lightweight and easy to install: The weight is only 1/8 of that of a metal elbow, making construction easy and reducing labor costs.

✅ Long life: Anti-aging, anti-ultraviolet (some models contain anti-UV additives), the service life can reach more than 50 years.

HDPE Buttfusion Stub End Adaptor Technical Specifications

Material:HDPE (PE80/PE100)

Connection Methods:Butt fusion

Pressure Rating:PN1.0MPa, PN1.6MPa PN2.0Mpa

Size Range:DN20mm ~ DN800mm (custom sizes available)

Operating Temperature:-40°C ~ +60°C

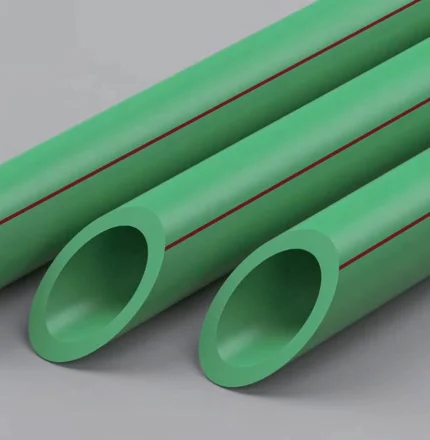

Color:Black (custom colors like blue/yellow for identification)

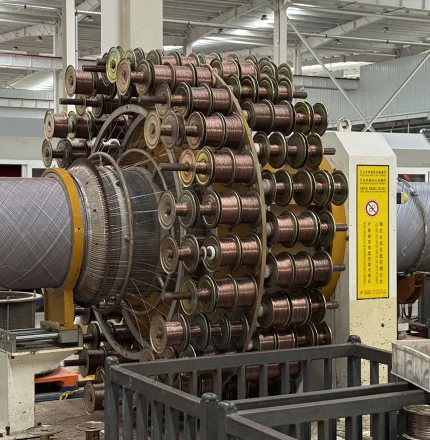

Injection molding of HDPE pipe fittings is a highly efficient and widely used production process. Its core involves injecting molten HDPE raw material into a mold using an injection molding machine, and after cooling and solidification, directly obtaining a complete pipe fitting.

Advantages of Injection Molded HDPE Pipe Fittings

High Structural Integrity

The fitting is molded as a single piece, without splicing or welding seams, avoiding the risk of leakage due to weak joints, resulting in superior sealing and pressure resistance.

High Production Efficiency

Automated injection molding processes enable rapid cycle production (single-piece molding cycle is typically tens of seconds to minutes), suitable for the mass production of standardized pipe fittings (such as elbows, tees, flanges, etc.).

Dimensional Accuracy and Consistency

Precision machining of the mold ensures stable pipe fitting dimensions and small tolerances, suitable for standardized piping system installation, reducing on-site adaptation issues.

Good Material Property Retention

During the melt injection molding process, HDPE molecular chains are evenly distributed, avoiding material degradation or stress concentration caused by secondary processing, maintaining excellent corrosion resistance and impact resistance.

SIZE(dn) | SDR17 | SDR11 | SDR9 |

L63 | √ | √ | √ |

L75 | √ | √ | √ |

L90 | √ | √ | √ |

L110 | √ | √ | √ |

L125 | √ | √ | √ |

L140 | √ | √ | √ |

L160 | √ | √ | √ |

L180 | √ | √ | √ |

L200 | √ | √ | √ |

L225 | √ | √ | √ |

L250 | √ | √ | √ |

L280 | √ | √ | √ |

L315 | √ | √ | √ |

L355 | √ | √ | √ |

L400 | √ | √ | √ |

L450 | √ | √ | √ |

L500 | √ | √ | √ |

L560 | √ | √ | √ |

L630 | √ | √ | √ |

L710 | √ | √ | √ |

L800 | √ | √ | √ |