Shandong Siffo Plastic Technology Co.,Ltd

Quality Control

SIFFO Pipe is a manufacturer of various pipes and fittings, possessing a quality control laboratory equipped with state-of-the-art facilities. Through precise product testing, SIFFO has successfully launched high-quality products that meet both internal and external standards. We are committed to improving operational efficiency, maintenance, and upgrades, and continuously enhancing product quality to achieve customer satisfaction.

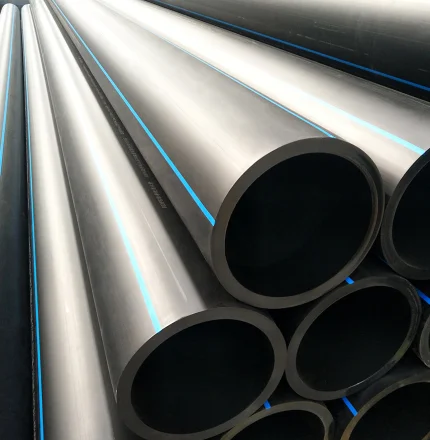

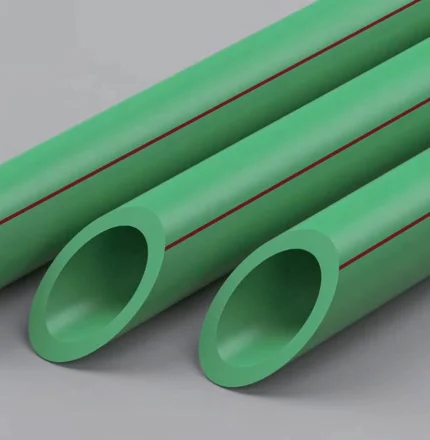

We, Shandong SIFFO Plastic Technology Co., Ltd., are a leading manufacturer of HDPE pipes, PVC pipes, SRTP (SRPE) pipes, corrugated drainage pipes, pipe fittings and piping systems.

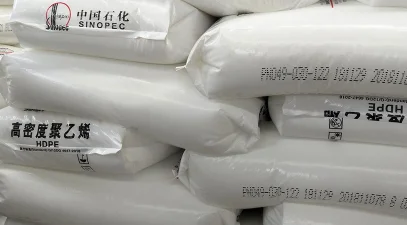

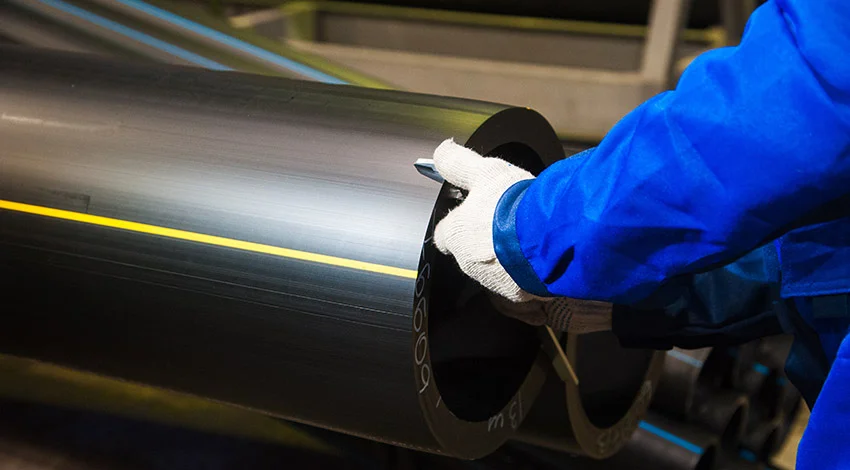

Raw Materials

SIFFO believes that superior piping products begin at the source – with an unwavering commitment to the highest standards of raw materials.

For HDPE pipes, we select premium high-density polyethylene virgin resin to ensure excellent resistance to environmental stress cracking and long-term hydrostatic strength. In PVC pipe production, we rigorously choose high-purity, high-impact polyvinyl chloride resin as the core base material. All raw materials undergo strict incoming inspection, with key indicators such as melt flow index, density, hygiene grade, and anti-aging additive content fully meeting standards. We insist on using raw materials that comply with international authoritative certifications such as ISO and NSF, eliminating any recycled materials or inferior fillers. This ensures the inherent safety, long lifespan, and stable performance of the piping system at the molecular level, laying a solid and reliable foundation for every project.

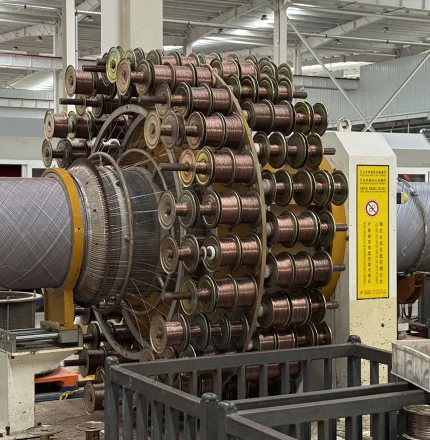

Production Management

Shandong SIFFO Plastics Co., Ltd. ensures quality through a four-pronged approach: "standard system + process control + technology verification + personnel management." Its core is not only meeting written standards, but also establishing an executable, traceable, and continuously improving quality culture.

Quality Inspection

Shandong SIFFO Plastics Co., Ltd. implements the most stringent factory inspections on finished pipes. Each pipe/batch undergoes long-term hydrostatic strength testing according to international standards (such as ISO and ASTM) to verify its reliability over a decades-long service life. Simultaneously, burst pressure testing ensures the pipes can withstand instantaneous pressure far exceeding the working pressure. Products also pass comprehensive testing for dimensional accuracy, appearance defects, and ring stiffness to ensure perfect matching with engineering designs. All key performance data are recorded and generated with unique traceability codes, enabling lifelong quality verification. Finally, all products receive authoritative certifications, guaranteeing 100% safety and reliability.

-

Can I have my own Logo on the product?

Sure,you just send us your drawing,we'll make logo for you and before production we will confirm with you in advance.

-

What is the delivery time of your products?

Usually 15-20 days. Delivery times will vary depending on the specific requirements of the order and our production schedule. Typically, standard products have shorter lead times, while custom products or bulk orders may have longer lead times. We will provide an estimated delivery time after order confirmation.

-

What standards for your HDPE pipes will comply with?

Our HDPE pipes are strictly manufactured according to international standards like ISO4427, EN12201, AS/NZS4130 etc.

-

If 3rd Party Inspection is available?

You can appoint any 3rd party inspection like BV, SGS etc to do the inspection, however, such expenses shall be for your account.

-

If could supply samples for our checking?

Yes, We can provide samples at your expenses(samples could be free, the shipping cost will be yours)

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.