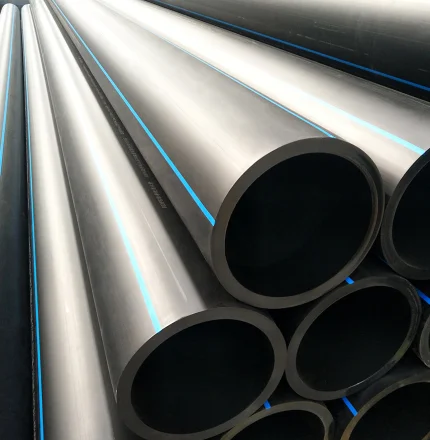

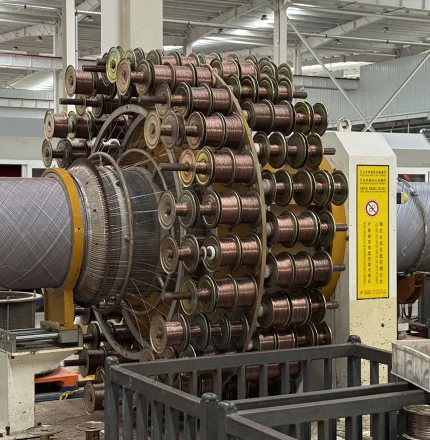

SIFFO HDPE Steel Strip Reinforced Spiral Corrugated Pipe is an innovative composite drainage pipe manufactured by advanced spiral winding technology combining high-density polyethylene (HDPE) with high-strength steel strips. This product perfectly integrates the corrosion resistance of HDPE with the high strength of steel strips, making it particularly suitable for municipal and industrial drainage projects requiring large diameters and high ring stiffness.

Parameter | Specification |

Material | HDPE + High-strength Steel Strip Composite |

Ring Stiffness | SN8, SN10,SN12.5, SN16 |

Diameter Range | DN600-DN3200mm |

Standard | ISO 21138,ISO 9969,EN 13476 ,CJ/T 225-2011 |

Single Length | 6m/9m/12m(customizable) |

Operating Temperature | -40℃ to +60℃ |

Jointing Methods | Electrofusion band connection, Stainless steel clamp connection |

Color | Black(standard), customizable |

Impact Resistance | ≥15kJ/m² |

Maximum Burial Depth | ≤20m(depending on ring stiffness) |

HDPE Steel Strip Reinforced Spiral Corrugated Pipe Features

Superior Structural Strength

Steel-Plastic Composite Reinforcement: Embedded steel strips provide extremely high ring stiffness (up to SN16 and above), offering strong resistance to external pressure.

Helical Corrugated Structure: The unique corrugated design increases the pipe's moment of inertia, improving its resistance to deformation.

Large Diameter Production Capacity: Capable of producing large-diameter pipes from 600-3200mm to meet various engineering needs.

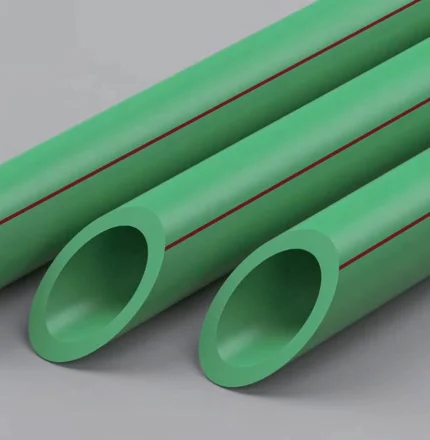

Excellent Material Properties

Chemical Corrosion Resistance: HDPE material resists acid, alkali, salt, and organic solvent corrosion, with a service life of over 50 years.

Good Flexibility: Possesses a certain degree of flexibility, adapting to uneven foundation settlement.

Low Temperature Impact Resistance: Maintains good toughness even at -60℃, suitable for use in cold regions.

Construction and Maintenance Advantages

Lightweight: Weighs only 1/10 of concrete pipes of the same specifications, facilitating transportation and installation.

Reliable Connections: Employs electrofusion tape or clamp-type elastic sealing connections, ensuring zero leakage at the joints.

Low Coefficient of Friction: Smooth inner wall reduces water flow resistance, increasing conveying capacity by 30% compared to traditional pipes. Maintenance-free design: No anti-corrosion treatment required, virtually maintenance-free.

Environmental and economical

Green and environmentally friendly: HDPE material is recyclable, and production energy consumption is low.

Low overall cost: Reduces the use of construction machinery, shortens the construction period, and lowers the overall project cost.

HDPE Steel Strip Reinforced Spiral Corrugated Pipe Application Scenarios

1.Municipal Drainage: Urban main road drainage systems, deep buried stormwater networks, wastewater treatment plant pipelines

2.Large Infrastructure: Drainage systems for airports, ports, railways, and expressways

3.Industrial Applications: Industrial wastewater systems for power plants, steel mills, and chemical plants

4.Special Geological Conditions: Drainage projects in soft ground, high water table areas, and seismic zones

5.Agricultural Water Conservancy: Large-scale farmland irrigation and drainage systems, reservoir drainage channels

6.Sponge City Construction: Ideal pipe material for rainwater collection and storage systems

Why Choose SIFFO HDPE Steel Strip Reinforced Pipes?

Innovative Structure: Unique steel-HDPE composite structure combines the best properties of both materials

Large Diameter Capacity: One of the few plastic pipes available in diameters up to 3000mm

Project Optimization: Our engineers can help design the most cost-effective solution for your specific project

Global References: Successfully implemented in major projects across Asia, Africa, and South America

Sustainable Solution: 100% recyclable materials with lower carbon footprint than traditional alternatives.

HDPE steel-reinforced spiral corrugated pipe, with its unique structural design and superior comprehensive performance, perfectly resolves the contradictions of traditional drainage pipes in terms of corrosion resistance, high strength, lightweight, and long service life. It is not only the preferred material for modern drainage system construction but also a key technological product for promoting high-quality infrastructure development. It demonstrates significant advantages in improving project quality, shortening construction time, and reducing total life-cycle costs, and has become one of the mainstream choices for large-scale drainage projects both domestically and internationally.

Ring Stiffness Rank | |||

Nominal Diameter | SN8 | SN10 | SN12.5 |

≥8KN/㎡ | ≥10KN/㎡ | ≥12.5KN/㎡ | |

External Diameter | External Diameter | External Diameter | |

(d. mm) | (d. mm) | (d. mm) | |

200 | 224 | 224 | |

300 | 325 | 325 | |

400 | 438 | 438 | |

500 | 539 | 539 | |

600 | 644 | 644 | 644 |

700 | 745 | 751 | 751 |

800 | 852 | 852 | 862 |

900 | 963 | 963 | 963 |

1000 | 1063 | 1063 | 1063 |

1100 | 1173 | 1173 | 1173 |

1200 | 1273 | 1273 | 1273 |

1300 | 1385 | 1385 | 1385 |

1400 | 1485 | 1485 | 1485 |

1500 | 1585 | 1585 | 1585 |

1600 | 1693 | 1693 | 1693 |

1700 | 1793 | 1793 | 1793 |

1800 | 1893 | 1893 | 1903 |

1900 | 2003 | 2003 | 2003 |

2000 | 2105 | 2105 | 2121 |

2100 | 2205 | 2205 | 2205 |

2200 | 2307 | 2323 | 2323 |

2400 | 2527 | 2527 | 2533 |

2600 | 2729 | 2729 | 2735 |

2800 | 2944 | 2944 | 2952 |

3000 | 3150 | 3150 | 3154 |

3200 | 3354 | 3354 | 3362 |