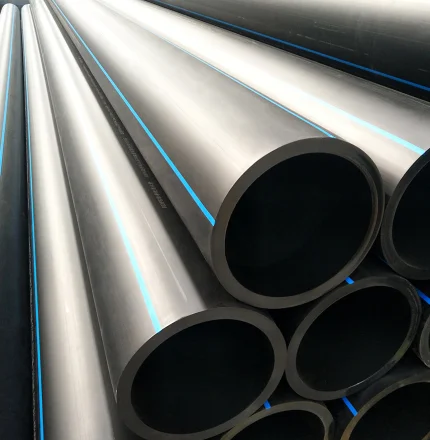

The 90° elbow is one of the most common and important pipe fittings in HDPE piping systems, mainly used to achieve right-angle changes in the direction of the pipe.The HDPE Buttfusion fittings developed and produced by SIFFO have excellent strength and wear resistance. They are specially designed for turning of pipeline systems to ensure smooth fluid delivery and reduce pressure loss. The product has excellent chemical corrosion resistance, high impact resistance and long life, and is suitable for a variety of application scenarios such as water supply and drainage, gas, chemical industry, and mining.

Product Features

✅ High strength and pressure resistance: Using PE80/PE100 grade raw materials, it has strong pressure bearing capacity and is suitable for pipeline systems of different pressure levels.

✅ Excellent corrosion resistance: It can resist the erosion of acids, alkalis, salts and various chemical media, and is suitable for chemical and sewage treatment environments.

✅ Flexible and earthquake-resistant: HDPE material has good flexibility, can adapt to foundation settlement and earthquake effects, and reduce the risk of pipeline rupture.

✅ Low flow resistance design: Smooth inner wall reduces fluid resistance and improves delivery efficiency.

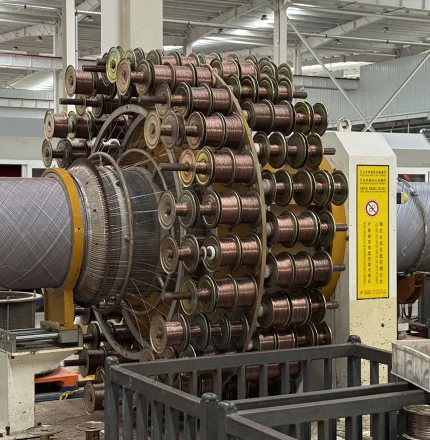

✅ Reliable hot-melt connection: Electric fusion or hot-melt butt connection is adopted to ensure seamless and leak-free interfaces.

✅ Lightweight and easy to install: The weight is only 1/8 of that of a metal elbow, making construction easy and reducing labor costs.

✅ Long life: Anti-aging, anti-ultraviolet (some models contain anti-UV additives), the service life can reach more than 50 years.

HDPE Buttfusion 90 Degree Elbow Technical Specifications

Material:HDPE (PE80/PE100)

Angle:90°

Connection Methods:Butt fusion

Pressure Rating:PN1.0MPa, PN1.6MPa PN2.0Mpa

Size Range:DN20mm ~ DN800mm (custom sizes available)

Operating Temperature:-40°C ~ +60°C

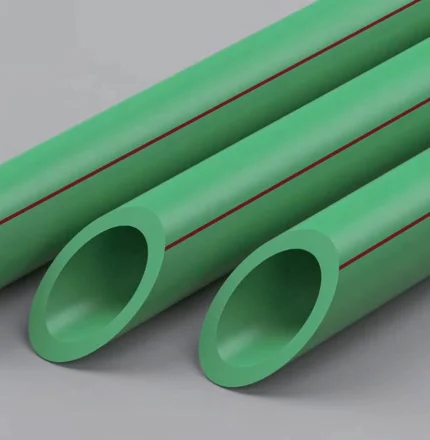

Color:Black (custom colors like blue/yellow for identification)

Key Features of 90° Elbows

Precise Angle Guidance

Provides accurate 90-degree directional changes, the most basic and commonly used turning angle in pipeline system layout and design, suitable for corner bends, equipment interfaces, and manhole access.

Superior Material Properties

Corrosion Resistance: Like HDPE pipes, it has excellent corrosion resistance to most chemicals (acids, alkalis, salts), suitable for various industrial fluids and municipal wastewater.

High Toughness and Impact Resistance: Not easily brittle even at low temperatures, it can withstand certain external impacts and internal water hammer pressure.

Smooth Inner Wall: Extremely low coefficient of friction, low water flow resistance, less prone to scaling, and good long-term water transport capacity retention.

Lightweight: Much lighter than metal elbows, facilitating transportation and installation, reducing labor intensity.

Excellent Connection Reliability

Through specialized equipment, the pipe and elbow ends are heated and melted together, then cooled to form a unified whole. The strength of the connection is even higher than the pipe itself, achieving zero leakage, making it the preferred choice for long-distance trunk pipelines.

Functions of a 90° Elbow

Changing the direction of fluid transport (core function)

This is the most basic function, enabling pipeline systems to make right-angle turns according to terrain, building layout, or process requirements, bypassing obstacles and achieving complex pipeline network layouts.

Reducing fluid transport resistance and optimizing hydraulic conditions

Compared to sharp bends or combinations of two 45° elbows fabricated on-site, standard injection-molded 90° elbows have smooth, streamlined curved inner walls (the bending radius is usually standard), which significantly reduces local head loss, lowers energy consumption, and ensures system transport efficiency.

SIZE(dn) | SDR17 | SDR11 | SDR9 |

L63 | √ | √ | √ |

L75 | √ | √ | √ |

L90 | √ | √ | √ |

L110 | √ | √ | √ |

L125 | √ | √ | √ |

L140 | √ | √ | √ |

L160 | √ | √ | √ |

L180 | √ | √ | √ |

L200 | √ | √ | √ |

L225 | √ | √ | √ |

L250 | √ | √ | √ |

L280 | √ | √ | √ |

L315 | √ | √ | √ |

L355 | √ | √ | √ |

L400 | √ | √ | √ |

L450 | √ | √ | √ |

L500 | √ | √ | √ |

L560 | √ | √ | √ |

L630 | √ | √ | √ |

L710 | √ | √ | √ |

L800 | √ | √ | √ |