HDPE pipe fittings – the cross fitting/four-way connector – is an important pipe fitting used to achieve four-way pipe branch connections. It is manufactured using an integral injection molding process, resulting in a strong overall structure, stable performance, and suitability for multi-directional fluid transport systems.

HDPE pipe fittings – the cross fitting/four-way connector – is an important pipe fitting used to achieve four-way pipe branch connections. It is manufactured using an integral injection molding process, resulting in a strong overall structure, stable performance, and suitability for multi-directional fluid transport systems.

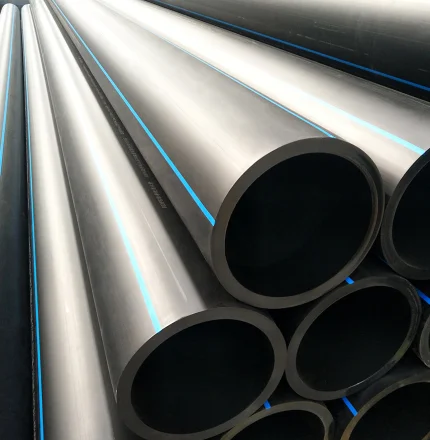

The HDPE Cross Fitting (Four-Way Connector) is an integral injection molded pipe fitting designed for multi-directional flow distribution in HDPE piping systems. Manufactured from high-quality high-density polyethylene (HDPE).

With its one-piece molded structure, the HDPE cross fitting eliminates weak joints, ensuring excellent pressure resistance and leak-free performance. The smooth internal surface reduces friction loss and improves fluid transmission efficiency.

This fitting supports various connection methods including butt fusion, electrofusion, and flange connections, making installation fast, secure, and cost-effective.

Main Features of HDPE Cross-Tee Joints:

1. One-piece injection molding, robust and reliable structure: Seamless, integral molding eliminates weak points caused by welding or assembly, providing high pressure resistance and suitability for long-term high-load operation.

2. Excellent corrosion and chemical resistance: HDPE material resists various acids, alkalis, and chemical media, making it suitable for harsh environments and industrial applications.

3. Good flexibility and impact resistance: Not prone to cracking under low temperature or geological settlement conditions, possessing excellent seismic and impact resistance.

4. Low fluid resistance: Smooth inner wall reduces head loss and improves conveying efficiency.

5. Multiple installation methods: Can be installed using butt fusion, electrofusion, or flange connections, making construction convenient and quick.

6. Long service life and low maintenance costs: Strong anti-aging properties, with a normal service life of over 50 years.

Main Applications of HDPE Cross-Type Four-Way Connectors:

1. Four-way Diversion or Merging in Piping Systems: Enables simultaneous distribution or recovery of fluid from the main pipe to multiple branches.

2. Irrigation Network Distribution Systems: Commonly used as connection nodes for multiple branches in agricultural sprinkler and drip irrigation systems.

3. Water Supply and Drainage Engineering: Cross-connection points in urban water supply and drainage systems.

4. Industrial Piping Systems: Used in multi-channel transportation scenarios such as chemical, water treatment, power, and mining industries.

5. Pipeline Network Renovation and Expansion Projects: Facilitates the addition of branch pipelines, improving system flexibility.