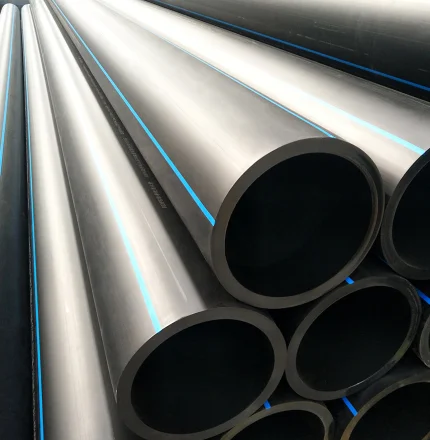

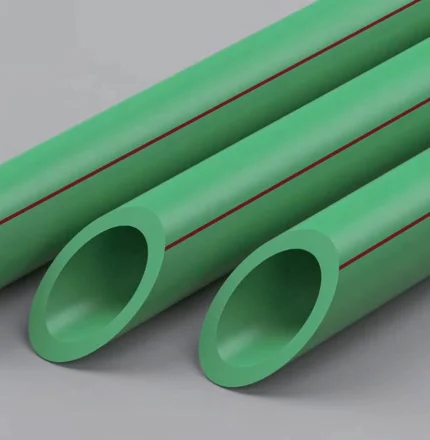

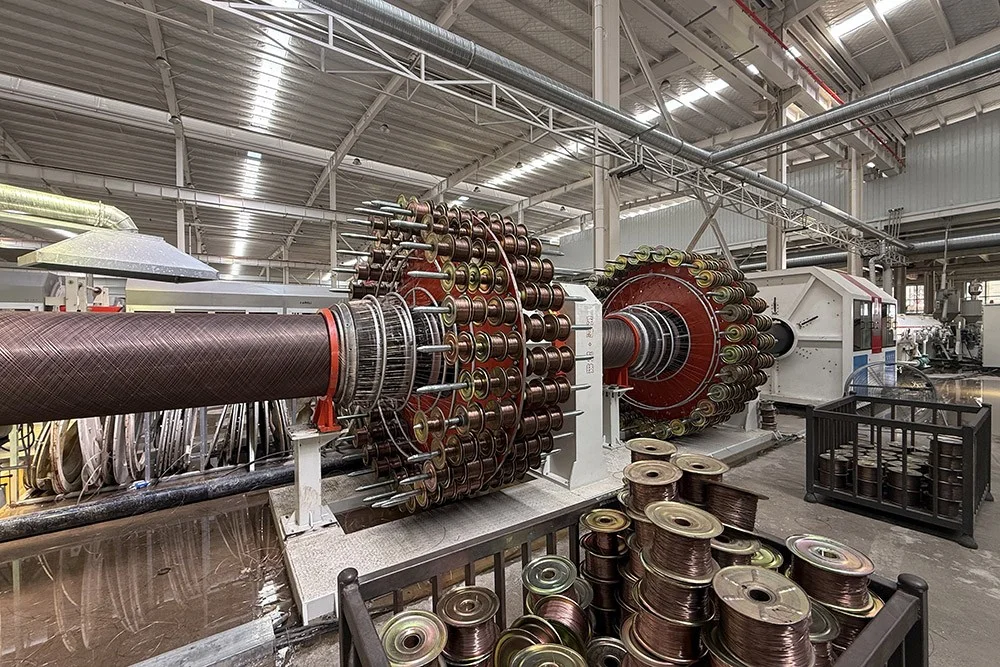

SIFFO HDPE Steel Wire Mesh Reinforced Composite Pipe (SRTP Pipe or SRPE Pipe) is an advanced piping solution combining high-density polyethylene (HDPE) with a high-tensile steel wire mesh skeleton. It integrates the corrosion resistance of plastic pipes with the strength of metal pipes, widely used in municipal water supply/drainage, oil & gas transmission, chemical fluid transport, mining tailings disposal, and agricultural irrigation—especially for high-pressure, long-distance, and geologically challenging projects.

Product Name | SIFFO Steel Wire Reinforced PE Pipe (SRTP,SRPE) |

Specification | DN50 - DN1000mm |

Pressure | PN8,PN10,PN16,PN20,PN25,PN30,PN35,PN40,PN50,PN63,PN70 |

Raw Material | 100% Virgin Material PE100 and steel wire |

Standards | ISO4437, EN1555, GB/T15558, ASTM D3035, AS/NZS4130, GOST18599, ASTM D2513,CJ/T189 |

Application | water supply, oil transportation, natural gas, mining,methane,, fire fight. |

Connection | Electrofusion Connection,Flange Connection |

Color | Black or Customized |

Product Series

Standard Type: For general pressure applications.

Reinforced Type: Higher pressure tolerance (up to 7.0MPa).

High-Temperature Type: Resists fluids up to 80°C (short-term 100°C).

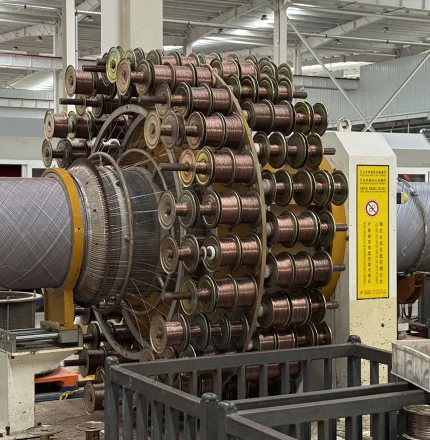

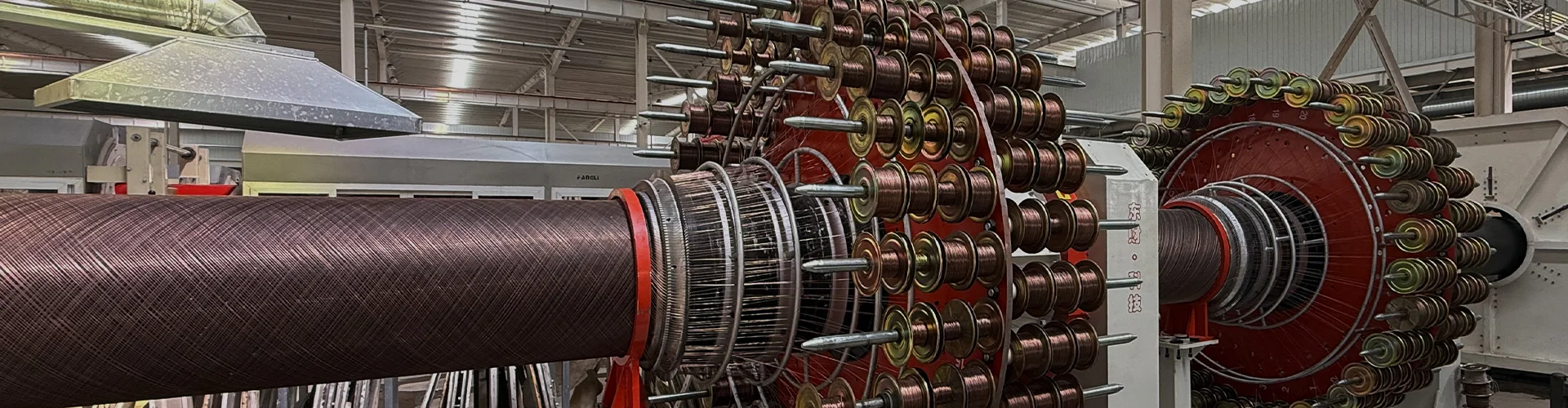

Steel Wire Reinforced PE Pipe Features

High Strength and High Pressure Resistance

The steel wire winding layer provides extremely high ring stiffness and impact resistance, with a pressure resistance far superior to pure PE pipes, reaching tens of megapascals (MPa), suitable for high-pressure transportation applications.

Excellent Flexibility and Deformation Resistance

The polyethylene matrix gives the pipe flexibility, adapting to foundation settlement or terrain changes; the steel wire reinforcement layer effectively resists external loads, preventing flattening or deformation.

Corrosion and Wear Resistance

The PE layer resists chemical media (acids, alkalis, salts) and electrochemical corrosion, requiring no anti-corrosion treatment; the smooth inner wall provides strong wear resistance and low resistance to the transported media.

Long Service Life and Low Maintenance Costs

Service life can reach over 50 years, with anti-aging properties (added UV stabilizers), requiring less frequent maintenance and resulting in low overall operation and maintenance costs.

Lightweight and Convenient Construction

Weighted significantly less than metal or concrete pipes, resulting in high transportation and installation efficiency; reliable sealing can be achieved through hot-melt butt welding, flange connections, etc.

Hygienic and Environmentally Friendly

PE material is non-toxic and odorless, meeting drinking water transportation standards; the production process has low energy consumption and is recyclable.

Steel Wire Reinforced PE Pipe Applications

Municipal Water Supply and Drainage Systems

High-pressure water supply, greywater reuse, rainwater discharge, especially suitable for deeply buried or geologically unstable areas.

Industrial Fluid Transportation

Mine tailings transportation, power plant ash and slag discharge, chemical media pipelines (high corrosion resistance required).

Agricultural Irrigation and Water Conservancy Projects

High-standard farmland sprinkler and drip irrigation systems, reservoir water conveyance, inter-basin water transfer projects.

Oil, Gas and Mining Sector

Oilfield water injection, coalbed methane transportation, high-pressure slurry pipelines, replacing some steel pipes to reduce corrosion risk.

Special Environmental Applications

Marine water pipelines (salt corrosion resistant), desert water transportation (UV resistant), earthquake zone pipeline projects (tensile strength resistant).

Pressure Rate | 0.8 Mpa | 1.0 Mpa | 1.25 Mpa | 1.6 Mpa | 2.0 Mpa | 2.5 Mpa | 3.0 Mpa | 3.5 Mpa | 4.0 Mpa | 5.0 Mpa | 6.3 Mpa | 7.0 Mpa |

Diameter (mm) | Wall thickness(mm) | |||||||||||

50 | - | 4.50 | 4.50 | 4.50 | 5.00 | 5.50 | 5.50 | 5.50 | 6.00 | 8.50 | 9.00 | 9.00 |

63 | - | 4.50 | 4.50 | 4.50 | 5.00 | 5.50 | 5.50 | 5.50 | 6.50 | 8.50 | 9.00 | 9.00 |

75 | - | 5.00 | 5.00 | 5.00 | 5.00 | 5.50 | 6.00 | 6.00 | 9.50 | 9.50 | 9.50 | 9.50 |

90 | - | 5.50 | 5.50 | 5.50 | 5.50 | 5.50 | 6.00 | 6.00 | 10.00 | 10.50 | 10.50 | 10.50 |

110 | - | 5.50 | 5.50 | 7.00 | 7.00 | 7.50 | 8.50 | 8.50 | 11.00 | 12.00 | 12.00 | 12.00 |

125 | - | 5.50 | 5.50 | 7.50 | 8.00 | 8.50 | 9.50 | 9.50 | 11.00 | 12.00 | 12.00 | 12.00 |

140 | - | 5.50 | 5.50 | 8.00 | 8.50 | 9.00 | 9.50 | 9.50 | 11.00 | 12.00 | 13.00 | 13.00 |

160 | - | 6.00 | 6.00 | 9.00 | 9.50 | 10.00 | 10.50 | 10.50 | 11.00 | 12.00 | 14.00 | 14.00 |

200 | - | 6.00 | 6.00 | 9.50 | 10.50 | 11.00 | 12.00 | 12.00 | 13.00 | 13.00 | 15.00 | 15.00 |

225 | - | 8.00 | 8.00 | 10.00 | 10.50 | 11.00 | 12.00 | 12.00 | 13.00 | 13.00 | ||

250 | 8.00 | 10.50 | 10.50 | 12.00 | 12.00 | 12.50 | 14.00 | 14.00 | 14.00 | 15.00 | ||

280 | 9.50 | 11.00 | 11.00 | 12.00 | 13.00 | 15.00 | 15.00 | 17.00 | 18.00 | |||

315 | 9.50 | 11.50 | 11.50 | 13.00 | 13.00 | 15.00 | 15.00 | 18.00 | ||||

355 | 10.00 | 12.00 | 12.00 | 14.00 | 14.00 | 17.00 | 17.00 | 19.00 | ||||

400 | 10.50 | 12.50 | 12.50 | 15.00 | 16.00 | 17.00 | 17.00 | - | ||||

450 | 11.50 | 13.50 | 13.50 | 16.00 | 18.00 | 18.00 | - | - | ||||

500 | 12.50 | 15.50 | 15.50 | 18.00 | 19.00 | 22.00 | - | - | ||||

630 | 20.00 | 23.00 | 23.00 | 26.00 | 26.00 | - | - | - | ||||

710 | 23.00 | 26.00 | 26.00 | 30.00 | - | - | - | - | ||||

800 | 27.00 | 30.00 | 30.00 | 34.00 | - | - | - | - | ||||

900 | 29.00 | 33.50 | 33.50 | 38.00 | - | - | - | - | ||||

1000 | 34.00 | 37.00 | - | - | - | - | ||||||