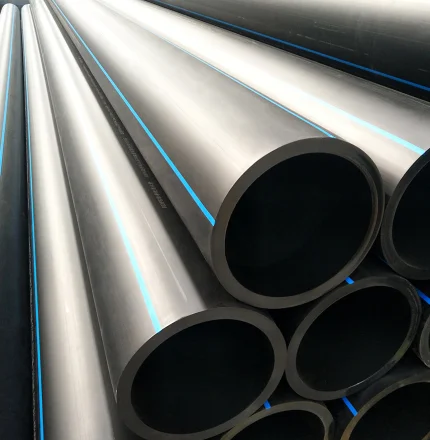

In the demanding world of drainage infrastructure, from pressurized systems to high-standard gravity flow applications, choosing the right piping material is critical for long-term performance, cost-effectiveness, and environmental sustainability. SIFFO Pipe, as a premier manufacturer and supplier of High-Density Polyethylene (HDPE) pipes, offers engineered solutions that excel where it matters most.

Why HDPE Pipes Are Ideal for Modern Drainage Projects

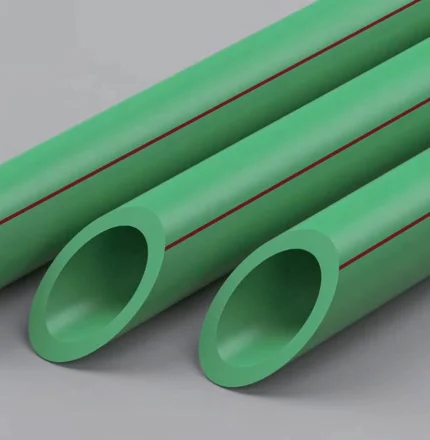

High-Density Polyethylene (HDPE) pipe represents a significant advancement over traditional materials like concrete, clay, or PVC. Its unique molecular structure provides a combination of properties perfectly suited for both pressurized drainage (force mains, outfalls, landfill leachate) and high-performance gravity flow systems (sewer mains, stormwater management, highway drainage).

Product Name | SIFFO Poly Drain Pipe |

Specification | DN20 - DN1600mm |

Pressure | SDR7.4-PN25,SDR9-PN20, SDR11-PN16, SDR13.6-PN12.5, SDR17-PN10, SDR21-PN8, SDR26-PN6 |

Raw Material | PE80 PE100 PE100-RC |

Standards | ISO 4427, AS/NZS 4130, BS EN 12201,DIN 8077 |

Application | Urban drink water supply |

Agricultural irrigation. | |

Sewage discharge. | |

Landscape garden water supply | |

Electrical Cable threading. | |

Connection | Butt fusion Welding, Electrofusion Welding |

Color | Black or Customized |

Key Characteristics of SIFFO HDPE Pipes

1. Superior Corrosion Resistance and Chemical Stability

No corrosion protection required: HDPE is an inert polymer material with extremely high corrosion resistance to most chemicals such as acids, alkalis, and salts. It will not undergo electrochemical corrosion or rusting. This is crucial for handling complex industrial wastewater, domestic sewage, and corrosive media in soil, resulting in a service life far exceeding that of metal pipes.

Wear Resistance: For slurries or wastewater containing solid particles, its inner wall wear resistance is superior to steel pipes, especially excelling in sand transportation.

2. Excellent Physical and Mechanical Properties

High Toughness and Impact Resistance: Even at low temperatures, HDPE pipes exhibit excellent impact resistance, unlike concrete or cast iron pipes which fracture brittlely. They effectively resist water hammer impacts, external loads, and stress from foundation settlement.

Good Flexibility: The pipes are bendable (bending radius is typically 20-25 times the pipe diameter), adapting to complex terrain and uneven settlement, reducing trench excavation and the use of elbows, and offering excellent seismic performance.

3. Reliable Connection Methods

Hot-fusion connection: Using a specialized hot-fusion welding machine, pipes and fittings are melted and connected into a unified system, with joint strength no less than that of the pipe body. This fundamentally eliminates joint leakage, protecting groundwater and the soil environment, and is one of the biggest advantages that traditional socket and flange connections cannot match.

Electrofusion connection: Suitable for confined spaces or repairs, achieving the same leak-free sealing effect.

4. Excellent Hydraulic Characteristics and High Flow Capacity

Absolutely smooth inner wall: Extremely low Manning coefficient (n-value) (approximately 0.009), with roughness far lower than steel and concrete pipes. Under the same pipe diameter and slope, flow capacity can be increased by more than 30%, or a smaller pipe diameter can be used to achieve the same flow rate, saving energy and reducing consumption.

Stable long-term water delivery capacity: No scaling, no microbial growth, and the inner wall roughness remains almost unchanged after long-term use, resulting in a high flow rate maintenance rate.

5. Lightweight and High-Strength, Convenient Construction

Lightweight: Weighing only 1/8 the weight of steel pipes and 1/10 the weight of concrete pipes per unit length, it is extremely convenient for transportation, handling, and installation, significantly reducing labor and machinery costs.

Fast Construction Speed: The connection process is quick and reliable, with low requirements for the construction environment, allowing for all-weather operation and significantly shortening the construction period.

6. Extra-Long Service Life

Long Design Life: Under rated temperature, pressure, and no direct UV radiation conditions, the design service life of HDPE pressure piping systems can reach over 50 years, resulting in low total life cycle costs.

Anti-Aging: High-quality UV stabilizers and antioxidants are added to the raw materials, making it suitable for open-air or shallow-buried installations.

7. Good Environmental Adaptability

Wide Temperature Range Applicable: Generally, it can be used safely in a temperature range of -60°C to 60°C.

Resistant to Frost Heave: Its flexibility can absorb stress caused by soil frost heave to a certain extent, reducing the risk of frost damage.

8. Outstanding Economic Efficiency

Low Overall Cost: Although the unit price of the material may not be the lowest, its lightweight, fast construction, lack of need for anti-corrosion treatment, extremely low maintenance costs, and long service life result in the most economical total life-cycle cost.

9. Environmentally Friendly and Recyclable

Recyclable Material: HDPE itself is an environmentally friendly material with low energy consumption during production and use. Waste pipes can be recycled and reused, aligning with sustainable development principles.

Application

For Pressurized Drainage (Force Mains):

Wastewater pipeline systems in wastewater treatment plants;

wastewater collection in large industrial parks;

basement toilets, kitchens, and laundry rooms;

underground commercial spaces and subway stations;

residential areas below the main municipal sewage pipes;

ships and RVs.

Our high-PN-rated pipes withstand constant pressure surges. The fused joint system guarantees zero leaks, protecting surrounding groundwater.

For Critical Gravity Sewers & Stormwater: Our SN-rated pipes ensure structural integrity under deep cover. The smooth bore minimizes blockages and maintains design flow rates, reducing long-term operational risks.

SIFFO Pipe Advantages: Beyond the Material

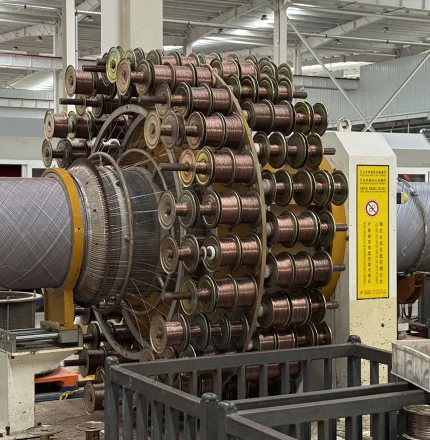

Choosing SIFFO Pipe means partnering with a supplier that controls quality from raw material to finished product. Our in-house manufacturing ensures:

Consistent, Certifiable Quality: We utilize premium-grade, virgin PE100/PE100RC compounds, producing pipes that meet and exceed international standards (ISO, EN, ASTM). Each batch is rigorously tested.

Engineered for Project Success: We offer a comprehensive range of diameters, pressure ratings (PN), and stiffness classes (SN), including tailored solutions for specific project challenges like deep bury or high water tables.

Cost-Effectiveness Over Lifecycle: While competitive on initial price, our HDPE pipes deliver superior value through reduced installation time (lightweight, long lengths), lower maintenance costs, and unparalleled longevity.

Partner with SIFFO Pipe for your next drainage project. As your direct factory source, we are committed to providing not just a product, but a reliable, high-performance drainage system backed by expertise and unwavering support.

Technical and Logistics Support: Our team provides full technical documentation, jointing procedure training, and reliable delivery scheduling to keep your project on track.

Specifications

This specification table is based on PE100 raw material, ISO4427, GB/T 13663, AS/NZS 4130 standards

Pressure | PN 6 | PN 8 | PN 10 | PN 12.5 | PN16 | PN 20 | PN 25 |

SDR | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 | SDR7.4 |

OD | Min Wall Thickness | ||||||

(mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

Φ20 | 2.30 | 2.30 | 3.00 | ||||

Φ25 | 2.30 | 2.30 | 3.00 | 3.50 | |||

Φ32 | 2.30 | 2.40 | 3.00 | 3.60 | 4.40 | ||

Φ40 | 2.30 | 2.40 | 3.00 | 3.70 | 4.50 | 5.50 | |

Φ50 | 2.30 | 2.40 | 3.00 | 3.70 | 4.60 | 5.60 | 6.90 |

Φ63 | 2.50 | 3.00 | 3.80 | 4.70 | 5.80 | 7.10 | 8.60 |

Φ75 | 2.90 | 3.60 | 4.50 | 5.60 | 6.80 | 8.40 | 10.30 |

Φ90 | 3.50 | 4.30 | 5.40 | 6.70 | 8.20 | 10.40 | 12.30 |

Φ110 | 4.20 | 5.30 | 6.60 | 8.10 | 10.00 | 12.30 | 15.10 |

Φ125 | 4.80 | 6.00 | 7.40 | 9.20 | 11.40 | 14.00 | 17.10 |

Φ140 | 5.40 | 6.70 | 8.30 | 10.30 | 12.70 | 15.70 | 19.20 |

Φ160 | 6.20 | 7.70 | 9.50 | 11.80 | 14.60 | 17.90 | 21.90 |

Φ180 | 6.90 | 8.60 | 10.70 | 13.30 | 16.40 | 20.10 | 24.60 |

Φ200 | 7.70 | 9.60 | 11.90 | 14.70 | 18.20 | 22.40 | 27.40 |

Φ225 | 8.60 | 10.80 | 13.40 | 16.60 | 20.50 | 25.20 | 30.80 |

Φ250 | 9.60 | 11.90 | 14.80 | 18.40 | 22.70 | 27.90 | 34.20 |

Φ280 | 10.70 | 13.40 | 16.60 | 20.60 | 25.40 | 31.30 | 38.30 |

Φ315 | 12.10 | 15.00 | 18.70 | 23.20 | 28.60 | 35.20 | 43.10 |

Φ355 | 13.60 | 16.90 | 21.10 | 26.10 | 32.20 | 39.70 | 48.50 |

Φ400 | 15.30 | 19.10 | 23.70 | 29.40 | 36.30 | 44.70 | 54.70 |

Φ450 | 17.20 | 21.50 | 26.70 | 33.10 | 40.90 | 50.30 | 61.50 |

Φ500 | 19.10 | 23.90 | 29.70 | 36.80 | 45.40 | 55.80 | |

Φ560 | 21.40 | 26.70 | 33.20 | 41.20 | 50.80 | 62.50 | |

Φ630 | 24.10 | 30.00 | 37.40 | 46.30 | 57.20 | 70.30 | |

Φ710 | 27.20 | 33.90 | 42.10 | 52.20 | 64.50 | 79.30 | |

Φ800 | 30.60 | 38.10 | 47.40 | 58.80 | 72.60 | 89.30 | |

Φ900 | 34.40 | 42.90 | 53.30 | 66.20 | 81.70 | ||

Φ1000 | 38.20 | 47.70 | 59.30 | 72.50 | 90.20 | ||

Φ1200 | 45.90 | 57.20 | 67.90 | 88.20 | |||

Φ1400 | 53.50 | 66.70 | 82.40 | 102.90 | |||

Φ1600 | 61.20 | 76.20 | 94.10 | 117.60 | |||

Performance Index

Item | Index | |

Elongation at break,% | >=350 | |

Longitudinal reversion (110℃),% | =<3 | |

Oxidation induction time (200℃),min | >=20 | |

Hydrostatic strengt | 20℃,100h | No cracking,no leakage |

PE80 10.0MPa | ||

PE100 12.4MPa | ||

80℃,165h | No cracking,no leakag | |

PE80 4.6MPa | ||

PE100 5.5MPa | ||

80℃,1000h | No cracking,no leakag | |

PE80 4.0MPa | ||

PE100 5.0MPa | ||