SIFFO Chlorinated Polyvinyl Chloride (CPVC) Chemical Pipes are engineered for aggressive industrial applications requiring superior thermal and chemical resistance. Manufactured under strict ASTM F441 guidelines, these pipes excel in high-temperature fluid transport (up to 93°C) while maintaining structural integrity. Ideal for corrosive environments in chemical plants, semiconductor facilities, and hot water systems.

Parameter | Details |

Material Grade | CPVC |

Standard | ASTM F441 |

Pressure Rating | SCH 40/80 (150-300 PSI) |

Operation Temperature | 0-93°C |

Size Range | 1/2", 3/4", 1", 1 1/4", 1 1/2", 2", 2 1/2", 3", 3 1/2", 4", 5", 6", 8", 10", 12", 14", 16", 18", 20", 24" (DN15-DN600) |

Thermal Conductivity | 0.14 W/m·K (insulating) |

ASTM F 441 CPVC Pipe Features

Superior Heat Resistance:

This is CPVC's core advantage. Its heat distortion temperature can reach over 90°C, and its long-term operating temperature can reach 82-93°C (depending on the specific formulation and pressure rating), far exceeding that of ordinary PVC (approximately 60°C). This makes it ideal for conveying hot water.

Excellent Corrosion and Chemical Resistance:

It has excellent resistance to most inorganic corrosive media such as acids, alkalis, and salts, and is not prone to scaling or bacterial growth.

It is unaffected by chloride ions in water, exhibits stable performance in electrochemical corrosive environments, and has a long service life.

Good Mechanical Properties and Pressure Bearing Capacity:

It can maintain sufficient mechanical strength for a long time under the standard-specified temperature and pressure. ASTM F441 specifies the minimum hydrostatic design basis (HDB) and pressure rating for pipes of different sizes and wall thicknesses (such as Schedule 40, 80).

Flame Retardant and Self-Extinguishing Properties:

With an oxygen index as high as 60, it is classified as a flame-retardant material. It self-extinguishes rapidly after the flame is removed, does not support combustion, and produces relatively low-toxicity smoke during combustion. This characteristic makes it suitable for use in fire protection systems.

Easy installation and low flow resistance:

Lightweight, only 1/6 the weight of steel pipes of the same size, making handling and installation easier.

Using solvent bonding (socket connection), the process is simple, fast, and highly reliable.

Smooth inner wall, low coefficient of friction, good hydraulic performance, and low energy consumption over long-term use.

Safe and hygienic:

Complies with NSF/ANSI 61 and other drinking water standards, does not release harmful substances into the water, and can be used in hot and cold drinking water systems.

ASTM F 441 CPVC Pipe Application Fields

Building Hot and Cold Water Supply Systems:

Hot water piping, especially in residential and commercial buildings, is its primary application market. It can be used in domestic hot water and heating systems (such as fan coil unit connection pipes) in hotels, hospitals, residences, schools, etc.

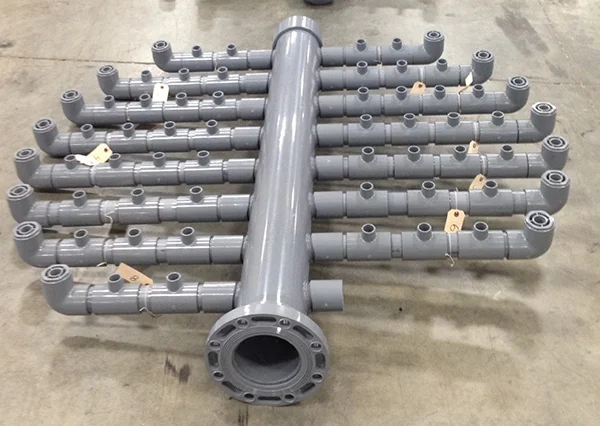

Industrial Piping Systems:

Chemical, electroplating, and electronics industries: Used for conveying various corrosive liquids, wastewater, and cooling water for process applications.

Food and Beverage Processing: Benefiting from its hygiene and corrosion resistance, it can be used for conveying process water and certain food media.

Fire Sprinkler Systems:

This is a very important and mature application for CPVC pipes. Specialized CPVC fire sprinkler pipes (such as BlazeMaster®) that comply with NFPA 13 and other fire protection standards are specifically designed for light and medium hazard wet fire sprinkler systems. Its advantages include quick installation, no welding required, and no rust clogging of sprinkler heads.

Swimming Pool and Spa Piping:

Resistant to hot water containing chlorine disinfectants, it is ideal for swimming pools, spas, and hot spring hot water circulation systems.

Other areas:

Solar water heating system piping, shipboard cold water and low-pressure seawater systems, etc.

Pipe Size (in.) | O.D. (in.) | Schedule 40 Dimensions (in) | Schedule 80 Dimensions (in) | ||

Average I.D. | Min. Wall | Average I.D. | Min. Wall | ||

1/4 | 0.540 | 0.344 | 0.088 | 0.282 | 0.119 |

3/8 | 0.675 | 0.473 | 0.091 | 0.403 | 0.126 |

1/2 | 0.840 | 0.602 | 0.109 | 0.526 | 0.147 |

3/4 | 1.050 | 0.804 | 0.113 | 0.722 | 0.154 |

1 | 1.315 | 1.029 | 0.133 | 0.936 | 0.179 |

1 1/4 | 1.660 | 1.360 | 0.140 | 1.255 | 0.191 |

1 1/2 | 1.900 | 1.590 | 0.145 | 1.476 | 0.200 |

2 | 2.375 | 2.047 | 0.154 | 1.913 | 0.218 |

2 1/2 | 2.875 | 2.445 | 0.203 | 2.290 | 0.276 |

3 | 3.500 | 3.042 | 0.216 | 2.864 | 0.300 |

3 1/2 | 4.000 | 3.521 | 0.226 | 3.326 | 0.318 |

4 | 4.500 | 3.998 | 0.237 | 3.786 | 0.337 |

5 | 5.563 | 5.016 | 0.258 | 4.768 | 0.375 |

6 | 6.625 | 6.031 | 0.280 | 5.709 | 0.432 |

8 | 8.625 | 7.942 | 0.322 | 7.565 | 0.500 |

10 | 10.750 | 9.976 | 0.365 | 9.493 | 0.593 |

12 | 12.750 | 11.889 | 0.406 | 11.294 | 0.687 |

14 | 14.000 | 13.073 | 0.437 | 12.410 | 0.750 |

16 | 16.000 | 14.940 | 0.500 | 14.213 | 0.843 |

18 | 18.000 | 16.809 | 0.562 | 16.014 | 0.937 |

20 | 20.000 | 18.743 | 0.593 | 17.814 | 1.031 |

24 | 24.000 | 22.544 | 0.687 | 21.418 | 1.218 |