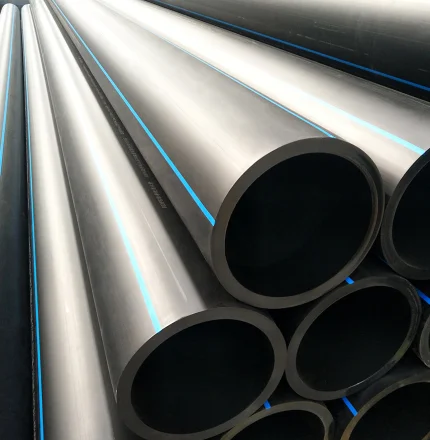

A reducing tee, as the name suggests, is a T-shaped pipe fitting with at least two of its three ends having different diameters. It contrasts with an equal-diameter tee (where all three ends have the same diameter).The HDPE Buttfusion fittings developed and produced by SIFFO have excellent strength and wear resistance. They are specially designed for turning of pipeline systems to ensure smooth fluid delivery and reduce pressure loss. The product has excellent chemical corrosion resistance, high impact resistance and long life, and is suitable for a variety of application scenarios such as water supply and drainage, gas, chemical industry, and mining.

Material Characteristics (Inheriting the Advantages of HDPE):

Excellent Corrosion Resistance: Resistant to various chemical media, requiring no anti-corrosion treatment, particularly suitable for wastewater and chemical industries.

High Toughness and Impact Resistance: Maintains good impact resistance even at low temperatures, not easily broken.

Good Flexibility and Settlement Resistance: Can adapt to uneven foundation settlement to a certain extent, with good seismic performance.

Smooth Inner Wall: Low frictional resistance, strong water conveyance capacity, and less prone to scaling.

Lightweight: Facilitates transportation and installation, reducing labor intensity.

Hot-Melt Butt Welding Performance: Can be hot-melted with pipes of the same material to form an integrated, leak-free connection, its core connection advantage.

HDPE Buttfusion Reducing Tee Technical Specifications

Material:HDPE (PE80/PE100)

Connection Methods:Butt fusion

Pressure Rating:PN1.0MPa, PN1.6MPa PN2.0Mpa

Size Range:DN20mm ~ DN800mm (custom sizes available)

Operating Temperature:-40°C ~ +60°C

Color:Black (custom colors like blue/yellow for identification)

Core Features of Reducing Tees

Structural Features:

T-shaped structure: The main pipe (running pipe) and branch pipe (sub-pipe) are connected at a 90-degree angle.

Reducing Diameter Design:

This is the most significant feature. There are usually two forms:

Main pipe with the same diameter at both ends, branch pipe with a different diameter: For example, 110mm × 110mm × 75mm (110mm * 75mm) indicates that the main pipe is 110mm and the branch pipe is 75mm.

Main pipe with a different diameter, branch pipe with a different diameter: For example, 160mm × 110mm × 75mm indicates that one end of the main pipe is 160mm and the other end is 110mm, and the branch pipe is 75mm.

Integrated Injection Molding:

High-quality HDPE reducing tees are typically manufactured using an integral injection molding process, without welds, resulting in good structural integrity and high strength.

The Main Functions of Reducing Tees

Reducing tees play a crucial role in piping systems as a "flow distribution and pipe diameter conversion hub," specifically in the following ways:

Flow Diversion and Merging:

Flow Diversion: Divides a portion of the fluid (water, gas, slurry, etc.) from the main pipe into branch pipes as needed, with the branch pipe flow typically less than the main pipe. For example, connecting a smaller pipe from a municipal water supply line to a residential area.

Merging: Merges fluid from branch pipes into the main pipe. For example, merging several smaller drainage pipes into a single main drainage pipe.

Changing Pipe Direction:

Enables 90-degree vertical turns in the piping system, facilitating complex pipe network layouts.

Achieving Pipe Diameter Transition (The Most Critical Function):

When connecting pipes of different diameters, reducing tees can smoothly and directly convert sizes without additional reducers. This makes pipe network design more flexible and compact, reducing connection points.

Optimizing System Design and Cost:

Economy: In situations where branch lines have lower flow requirements, using smaller diameter branch pipes can significantly save on material costs. Space adaptability: When installation space is limited, the pipe diameter can be varied to adapt to different layouts.

Pressure matching: By changing the pipe diameter, the fluid pressure in a local system can be adjusted to a certain extent.

Applications of Reducing Tees:

Municipal Water Supply and Drainage Systems: Supplying water from the main pipeline to branches in streets or residential areas; collecting sewage from branch lines into the main sewage pipe.

Agricultural Irrigation Systems: Splitting multiple branch pipes of different sizes from the main water supply pipeline to various irrigation areas.

Industrial Pipelines: Used for diversion and merging in systems such as chemical media transportation and mine tailings discharge.

Gas Transmission Systems: Used in PE gas pipelines for regional distribution within medium and low pressure networks.

SIZE | SDR17 | SDR11 | SDR9 |

63×50 | √ | √ | |

75×50 | √ | √ | |

75×63 | √ | √ | |

90×50 | √ | √ | √ |

90×63 | √ | √ | √ |

90×75 | √ | √ | √ |

110×50 | √ | √ | √ |

110×63 | √ | √ | √ |

110×75 | √ | √ | √ |

110×90 | √ | √ | √ |

125×63 | √ | √ | √ |

125×75 | √ | √ | √ |

125×90 | √ | √ | √ |

125×110 | √ | √ | √ |

140×63 | √ | √ | √ |

140×75 | √ | √ | √ |

140×90 | √ | √ | √ |

140×110 | √ | √ | √ |

140×125 | √ | √ | √ |

160×63 | √ | √ | √ |

160×75 | √ | √ | √ |

160×90 | √ | √ | √ |

160×110 | √ | √ | √ |

160×125 | √ | √ | √ |

180×90 | √ | √ | √ |

180×110 | √ | √ | √ |

180×125 | √ | √ | |

180×140 | √ | √ | |

180×160 | √ | √ | √ |

200×63 | √ | √ | √ |

200×75 | √ | √ | √ |

200×90 | √ | √ | √ |

200×110 | √ | √ | √ |

200×125 | √ | √ | √ |

200×160 | √ | √ | √ |

200×180 | √ | √ | √ |

225×63 | √ | √ | √ |

225×75 | √ | √ | √ |

225×90 | √ | √ | √ |

225×110 | √ | √ | √ |

225×125 | √ | √ | |

225×140 | √ | √ | |

225×160 | √ | √ | √ |

225×200 | √ | √ | √ |

250×63 | √ | √ | |

250×75 | √ | √ | |

250×90 | √ | √ | √ |

250×110 | √ | √ | √ |

250×160 | √ | √ | √ |

250×200 | √ | √ | √ |

280×110 | √ | √ | √ |

280×160 | √ | √ | √ |

280×200 | √ | √ | √ |

280×250 | √ | √ | √ |

315×90 | √ | √ | √ |

315×110 | √ | √ | √ |

315×160 | √ | √ | √ |

315×200 | √ | √ | √ |

315×250 | √ | √ | √ |

355×110 | √ | √ | √ |

355×125 | √ | √ | |

355×140 | √ | √ | |

355×160 | √ | √ | √ |

355×180 | √ | √ | |

355×200 | √ | √ | √ |

355×225 | √ | √ | |

355×250 | √ | √ | √ |

355×280 | √ | √ | |

355×315 | √ | √ | √ |

400×110 | √ | √ | √ |

400×125 | √ | √ | √ |

400×140 | √ | √ | √ |

400×160 | √ | √ | √ |

400×180 | √ | √ | |

400×200 | √ | √ | √ |

400×225 | √ | √ | |

400×250 | √ | √ | √ |

400×280 | √ | √ | |

400×315 | √ | √ | √ |

400×355 | √ | √ | √ |

450×110 | √ | √ | √ |

450×160 | √ | √ | √ |

450×200 | √ | √ | √ |

450×250 | √ | √ | √ |

450×315 | √ | √ | √ |

450×400 | √ | √ | √ |

500×110 | √ | √ | √ |

500×160 | √ | √ | √ |

500×200 | √ | √ | √ |

500×250 | √ | √ | √ |

500×315 | √ | √ | √ |

500×400 | √ | √ | √ |

560×110 | √ | √ | √ |

560×160 | √ | √ | √ |

560×200 | √ | √ | √ |

560×250 | √ | √ | √ |

560×315 | √ | √ | √ |

560×400 | √ | √ | √ |

560×500 | √ | √ | √ |

630×110 | √ | √ | √ |

630×160 | √ | √ | √ |

630×200 | √ | √ | √ |

630×250 | √ | √ | √ |

630×315 | √ | √ | √ |

630×400 | √ | √ | √ |

630×500 | √ | √ | √ |

710×110 | √ | √ | √ |

710×160 | √ | √ | √ |

710×200 | √ | √ | √ |

710×250 | √ | √ | √ |

710×315 | √ | √ | √ |

710×400 | √ | √ | √ |

710×500 | √ | √ | √ |

710×630 | √ | √ | √ |

800×110 | √ | √ | √ |

800×160 | √ | √ | √ |

800×200 | √ | √ | √ |

800×250 | √ | √ | √ |

800×315 | √ | √ | √ |

800×400 | √ | √ | √ |

800×500 | √ | √ | √ |

800×630 | √ | √ | √ |

800×710 | √ | √ | √ |