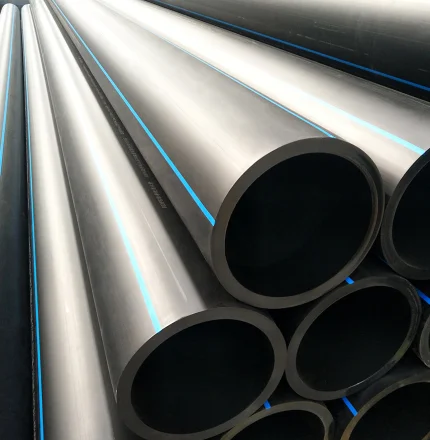

SIFFO HDPE (High-Density Polyethylene) electrofusion fittings are specially designed for joining HDPE pipes using electrofusion welding technology. These fittings have built-in heating wires that melt the pipe and fitting surfaces when an electric current is applied, creating a strong, leak-proof joint. They are widely used in gas, water supply, industrial pipelines, and mining applications due to their durability and corrosion resistance.

Key Features

·Strong & Leak-proof – Ensures a homogeneous fusion for a permanent joint.

·Corrosion Resistant – Suitable for aggressive environments.

·Easy Installation – Requires minimal equipment and labor.

·Long Service Life – Resistant to chemicals and UV radiation.

·High Pressure Resistance – Suitable for high-pressure fluid transport.

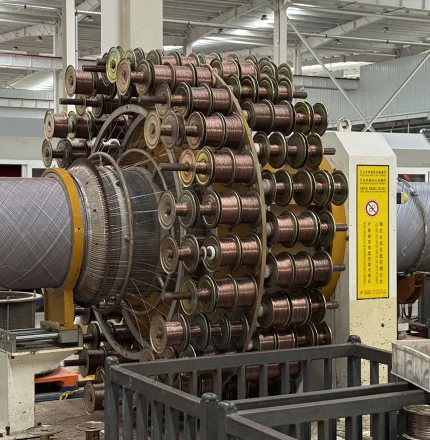

Electrofusion fittings mainly include equal diameter straight connectors, reducing straight connectors, equal diameter tees, reducing tees, equal diameter 90°/45° elbows, flanges, etc., used to connect plastic piping systems. HDPE electrofusion fittings are a type of heat fusion welding, referring to plastic fittings where metal wires are embedded inside the pipe ends. Heating with an electric current causes the resistance wires on the inner surface of the fitting to heat up, thus fusing the pipe and fitting together. Due to price considerations, heat fusion fittings are used more frequently than electrofusion fittings in engineering applications. However, electrofusion fittings play an important and irreplaceable role in engineering and maintenance, especially during construction where they are less affected by external environmental and human factors, resulting in better reliability and greater user appeal. Electrofusion fittings are increasingly used, particularly in gas pipeline projects.

HDPE Electrofusion Technical Specifications

Material:HDPE (PE80/PE100)

Connection Methods:Butt fusion

Pressure Rating:PN1.0MPa, PN1.6MPa PN2.0Mpa PN2.5Mpa PN3.0Mpa PN4.0Mpa

Size Range:DN20mm ~ DN800mm (custom sizes available)

Operating Temperature:-40°C ~ +60°C

Color:Black (custom colors like blue/yellow for identification)

HDPE Electrofusion Fitting Installation Steps

1. Cut the pipe vertically. Use a scraper to remove the surface oxide layer from the section of the pipe to be inserted into the electrofusion fitting.

2. Mark the insertion depth of the electrofusion fitting on the pipe surface using a marker.

3. Insert the pipe into the electrofusion fitting to the marked depth, ensuring the pipe's centerline coincides with the fitting's.

4. Secure the pipe and fitting together using clamps to prevent misalignment or loosening during welding.

Key Features of HDPE Electrofusion Fittings

Reliable Connection and Excellent Sealing

By electrically heating a resistance wire embedded in the fitting, both the inner and outer surfaces of the fitting and the pipe melt simultaneously. The polyethylene molecular chains diffuse and fuse, forming a unified connection with strength no less than the pipe itself after cooling. This fundamentally avoids joint leakage problems, making it particularly suitable for applications with extremely high sealing requirements, such as gas and water supply systems.

Simple Construction and High Efficiency

The technical requirements for operators are relatively low (compared to butt fusion), requiring only three key steps: scraping, alignment, and applying electricity.

Less affected by environmental factors (such as strong winds or confined spaces) and human error, making it easier to ensure consistent quality.

Fast installation speed, suitable for emergency repairs and projects with a large number of joints.

Highly adaptable and flexible in application

Especially suitable for operations in confined spaces (such as foundation pits, between existing pipes) or where large thermofusion equipment cannot be used.

High structural strength and good system integrity

Electrofusion sleeves and other fittings can reinforce the joints, improving the overall compressive, tensile, and shear resistance of the system.

SIZE(dn) | PN10 | PN16 | PN20 |

L63 | √ | √ | √ |

L75 | √ | √ | √ |

L90 | √ | √ | √ |

L110 | √ | √ | √ |

L125 | √ | √ | √ |

L140 | √ | √ | √ |

L160 | √ | √ | √ |

L180 | √ | √ | √ |

L200 | √ | √ | √ |

L225 | √ | √ | √ |

L250 | √ | √ | √ |

L280 | √ | √ | √ |

L315 | √ | √ | √ |

L355 | √ | √ | √ |

L400 | √ | √ | √ |

L450 | √ | √ | √ |

L500 | √ | √ | √ |

L560 | √ | √ | √ |

L630 | √ | √ | √ |

L710 | √ | √ | √ |

L800 | √ | √ | √ |