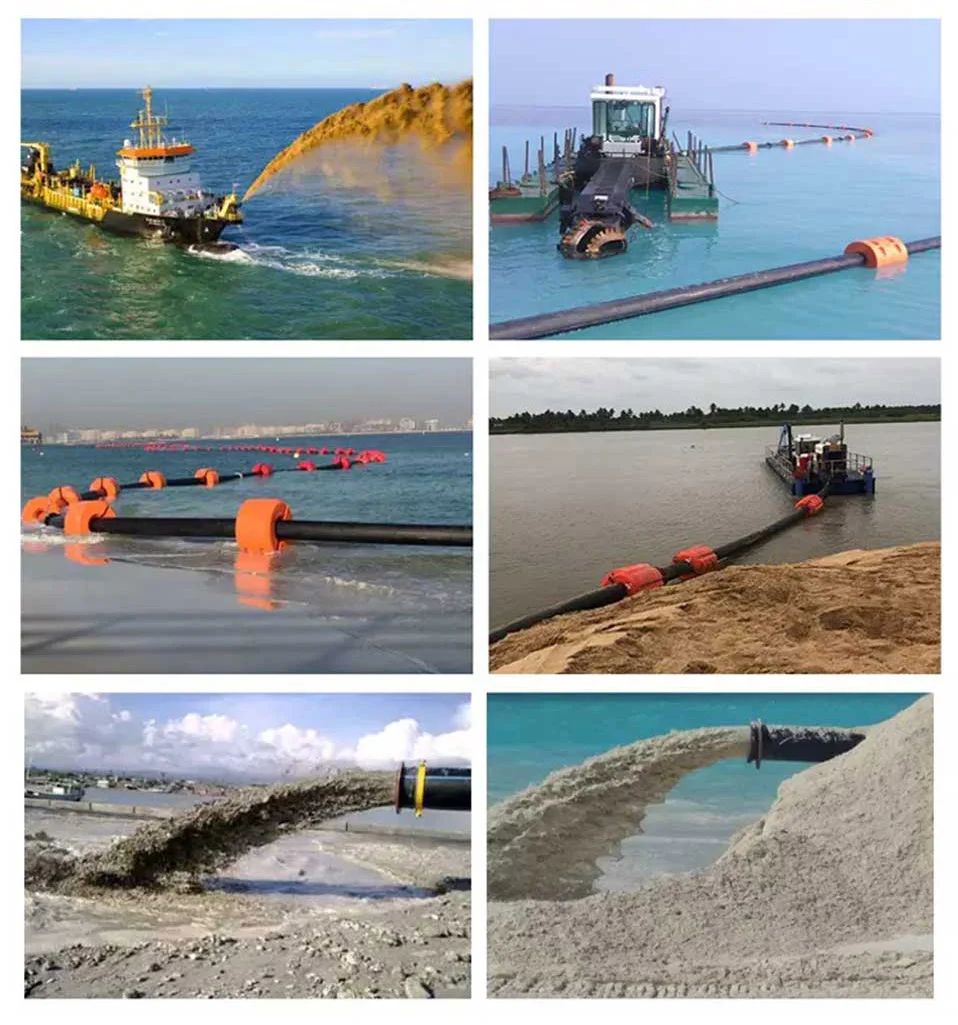

The main function of HDPE dredging pipe is to clean up HDPE pipes that transport sediment, mud and other mixed debris. The purpose is to: excavate harbors, access channels, etc., to build docks, port areas and port industrial areas, coastal urban land and entertainment and leisure land, shore maintenance, water conservancy flood control and reservoir dredging, water environment improvement and ecological restoration of rivers, lakes and seas, and construction and landfill of various underwater pipeline trenches.

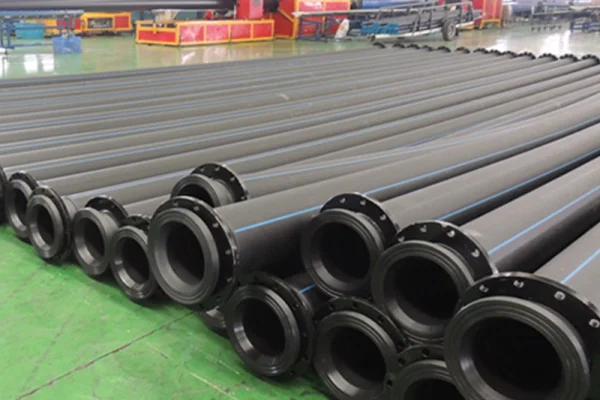

| Product Name | SIFFO HDPE Dredging Pipe |

| Specification | DN110 - DN1200mm |

| Pressure | SDR9-PN20, SDR11-PN16, SDR13.6-PN12.5, SDR17-PN10, SDR21-PN8, SDR26-PN6 |

| Raw Material | PE80 PE100 PE100-RC |

| Standards | ISO 4427, AS/NZS 4130, BS EN 12201,DIN 8077 |

| Application | Coastal Construction |

| Beach maintenance | |

| Water Conservancy and Flood Control | |

| Reservoir desilting | |

| Sewage discharge | |

| Connection | Flange connection |

| Color | Black or Customized |

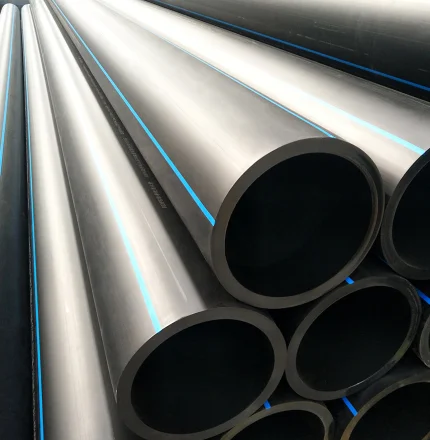

When it comes to the demanding tasks of river desilting, harbor deepening, waterway maintenance, and offshore sand mining, the pipeline system is the lifeline of the operation. HDPE (High-Density Polyethylene) dredging pipes are specifically engineered to excel in these challenging environments, outperforming traditional materials like steel in efficiency, durability, and total cost of ownership.

Why HDPE is Ideal for Dredging and Sand Pumping

Unmatched Abrasion Resistance: The inner wall of HDPE pipe is exceptionally smooth and tough, offering superior resistance to the relentless wear caused by sand, silt, gravel, and other abrasive solids in slurry. This translates to longer pipe life and consistent flow rates.

Superior to Corrosion & Rust: Operating in saltwater, brackish water, or chemically variable freshwater poses no threat. HDPE is completely inert to electrochemical corrosion, rust, and a wide range of chemicals, eliminating a major failure point of steel pipes.

Buoyant & Easy to Handle on Water: Its lightweight nature is a game-changer for marine applications. HDPE pipes are easier to deploy, reconfigure, and retrieve from water. They can be fitted with integrated flotation systems, simplifying the setup of long-distance floating pipelines.

Leak-Proof & Reliable Connections: Using integrated flange connections or butt-fusion welding, HDPE pipelines create monolithic, leak-free systems. This prevents loss of valuable slurry, environmental contamination, and avoids the constant maintenance headaches of leaking flange gaskets common in steel systems.

Flexible & Impact Resistant: The natural flexibility of HDPE allows it to withstand waves, currents, and minor impacts from vessels or debris without damage. It can also adapt to uneven riverbeds or seabeds during bottom-pull installations.

HDPE Dredging Pipe Application Area

1. HDPE Dredging Pipes for Above-Sea Sludge Discharge Operations

Application Scenarios: Floating pipes or shore pipes connecting dredgers to land-based sludge discharge sites; some sections may be exposed to air.

Detailed Description and Comparison: HDPE pipes are lightweight, facilitating splicing and towing on water. Their excellent UV resistance (through the addition of carbon black) and weather resistance allow them to withstand long-term exposure to sunlight and salt spray corrosion, while steel pipes corrode rapidly under these conditions, requiring frequent anti-corrosion maintenance. Their flexibility makes them safer in rough seas.

2.HDPE Dredging Pipes Used in Lake Dredging Projects

Application Scenarios: Eutrophication control, removal of polluted sediment, and increasing reservoir capacity.

Detailed Description and Comparison: The transported sediment may contain organic pollutants or slightly acidic or alkaline substances. HDPE pipes' chemical corrosion resistance ensures the pipes are not corroded, and their smooth inner walls prevent scale buildup and clogging. Compared to concrete pipes, they are lighter, making them easier to install in environmentally sensitive areas with high requirements, minimizing disturbance to the surrounding ecosystem.

3. Application of HDPE Dredging Pipes in Mining Projects

Application Scenarios: Tailings transportation, slurry transportation, seabed mining, etc.

Detailed Explanation and Comparison: Slurries are typically highly abrasive. The superior abrasion resistance of HDPE pipes is the decisive factor in their replacement of steel pipes in the mining field. Steel pipes are quickly punctured under high pressure and high abrasion, while HDPE pipes have a longer lifespan. Their flexibility also adapts to the complex terrain variations of mining areas.

4. HDPE Dredging Pipes for Use in the Chemical Industry

Application Scenarios: River dredging in chemical plant areas, dredging at wharf shorelines; the transported slurry may contain chemical residues.

Detailed Explanation and Comparison: This environment places stringent requirements on the chemical resistance of pipelines. HDPE can withstand various acid, alkali, and salt media, making it one of the preferred anti-corrosion materials in the chemical industry. In contrast, even with lining, steel pipes have the risk of seams and breakage, resulting in high maintenance costs and hazards.

5. River Discharge Applications Also Prefer High-Density Polyethylene Dredging Pipes

Application Scenarios: River regulation, flood control dredging, sediment discharge to designated areas. Detailed Explanation and Comparison: Projects are often located in remote or topographically complex areas. HDPE pipes are lightweight and can be pre-welded into sections hundreds of meters long for rapid laying on riverbanks, swamps, or floating on water. Their flexibility adapts to river bends, reducing connection points. Concrete pipes are cumbersome and prone to damage due to settlement in such dynamic environments.

6. Application of high-density polyethylene dredging pipes in dredging sea sand.

Application Scenarios: Sea sand extraction for construction or beach maintenance.

Detailed Explanation and Comparison: Sea sand is salty, highly corrosive, and contains abrasive materials such as shells. HDPE pipes perfectly utilize their resistance to both corrosion and abrasion. As floating pipes, their high buoyancy and resistance to marine organism adhesion are also superior to steel pipes, which require frequent cleaning and maintenance.

7.HDPE Dredging Pipes suitable for marine outfalls

Application Scenarios: Discharging treated dredged material (or wastewater effluent) to designated deep-sea locations via underwater pipelines.

Detailed Description and Comparison: This is for permanent or long-term subsea installation. HDPE pipes can be designed for negative buoyancy (sinking) or with pontoons. Its fully fused structure ensures zero leakage, protecting the marine ecosystem. Excellent resistance to seawater corrosion and long lifespan avoid the environmental disasters and high replacement costs caused by corrosion perforation, as seen with steel pipes.

8. Application of HDPE Dredging Pipes in Agricultural Projects

Application Scenarios: Irrigation channel dredging, reservoir expansion, fishpond renovation, etc.

Detailed Description and Comparison: Projects typically have limited budgets and require safe water quality. HDPE pipes are cost-effective, quick to install, and cause minimal disruption to agricultural operations. Their non-toxic properties ensure that the transported water or slurry will not be subject to secondary pollution, making them suitable for subsequent agricultural use.

9. HDPE Dredging Pipes for Dock Projects

Application Scenarios: Harbor basin and channel maintenance dredging, new dock foundation trench excavation.

Detailed Description and Comparison: Dock areas experience frequent vessel traffic, and pipelines may be subject to collisions. HDPE pipes' impact resistance and toughness make them less prone to breakage upon accidental impact, only deforming, thus reducing the risk of drainage shutdowns. Their rapid disassembly and reassembly capabilities also adapt to the busy operational rhythm of docks. Steel pipes, on the other hand, are easily dented and cracked after impact, making repairs difficult.

10. Application of HDPE Dredging Pipes in Offshore Operations

Application Scenarios: Deep-sea dredging, deep-sea mining, offshore island and reef construction, etc.

Detailed Explanation and Comparison: This is the field with the highest requirements for pipeline reliability. Under harsh sea conditions, the flexibility of HDPE floating pipe systems can absorb wave energy, resulting in greater survivability. The extra-long single pipe sections reduce the number of joints at sea, lowering the potential for failure. Their corrosion resistance and maintenance-free characteristics greatly reduce the need for high-risk, high-cost maintenance operations in remote sea areas, making their overall safety and economy superior to traditional steel pipes.

Dredging Floats

The dredging pipeline floats, which can absorb or reduce the energy generated by the collision of waves against ships. The outside of the float is made of LDPE or MDPE, which has the characteristics of low cost and high strength, and the inside is filled with polyurethane. The dredging pipe float consists of two halves, each half can be placed on the HDPE dredging pipe, secured with steel bolts and nuts or bandages.

Specifications

This specification table is based on PE100 raw material, ISO4427, GB/T 13663, AS/NZS 4130 standards.

| Nominal pressure | PN 6 | PN 8 | PN 10 | PN 12.5 | PN16 | PN 20 |

| Standard dimension ratio | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 |

| Nominal outside diameter | Thickness | Thickness | Thickness | Thickness | Thickness | Thickness |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

| Φ110 | 4.2 | 5.3 | 6.6 | 8.1 | 10 | 12.3 |

| Φ125 | 4.8 | 6 | 7.4 | 9.2 | 11.4 | 14 |

| Φ140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 |

| Φ160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 |

| Φ180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 |

| Φ200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 |

| Φ225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | 25.2 |

| Φ250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 |

| Φ280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 |

| Φ315 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | 35.2 |

| Φ355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 |

| Φ400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 |

| Φ450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 |

| Φ500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 |

| Φ560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 |

| Φ630 | 24.1 | 30 | 37.4 | 46.3 | 57.2 | 70.3 |

| Φ710 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 |

| Φ800 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 |

| Φ900 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | |

| Φ1000 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | |

| Φ1200 | 45.9 | 57.2 | 67.9 | 88.2 |