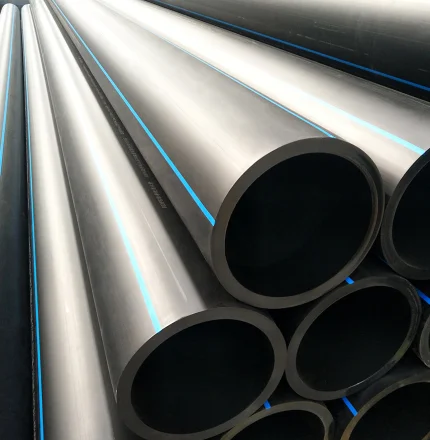

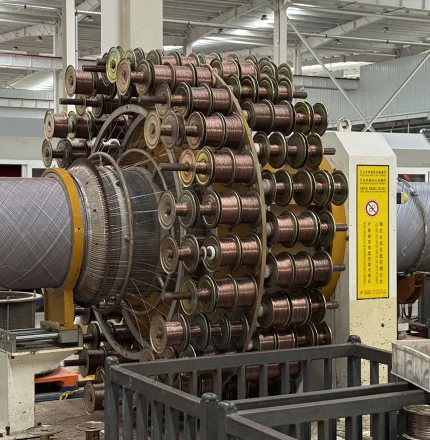

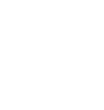

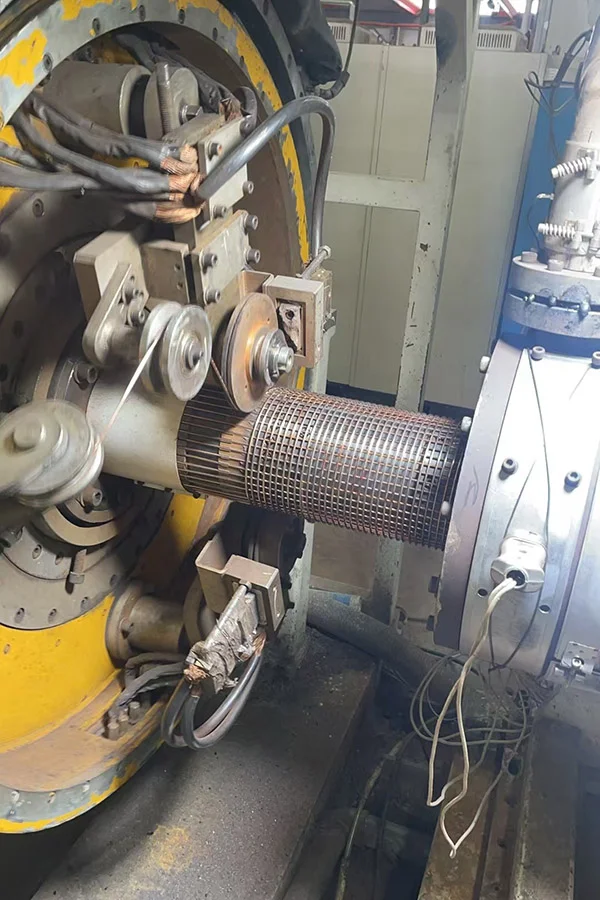

SIFFO high-density polyethylene (HDPE) steel skeleton reinforced composite pipe (SRPE pipe ) is a composite pipe with high-density polyethylene (HDPE) in both inner and outer layers, with a steel skeleton embedded in the middle. The steel skeleton is made of high steel-strength steel wires welded in a criss-cross pattern. This provides high tensile strength, enhances the strength of the pipe body, and has high pressure resistance. In addition, the inner and outer layers use HDPE or PE100 RC as raw materials, which can be made into lightweight pipes that are resistant to corrosive chemicals and withstand freeze-thaw cycles and continuous sub-zero temperatures without cracking. It is also highly wear-resistant and is not affected by acids and alkalis. In some high-temperature applications, the internal raw material can be adjusted to PERT, so that the SIFFO SRPE pipe has good temperature resistance, and the maximum operating temperature can reach 80 ℃. This product combines the corrosion resistance of plastic pipes with the high strength of metal pipes. It is widely used in the fields of petroleum, natural gas, chemical industry, municipal water supply and drainage, mining, electric power, marine engineering, etc., especially suitable for the transportation of high-pressure, high-temperature, and highly corrosive media.

Product Name | SIFFO HDPE Steel Skeleton Reinforced Composite Pipe (SRTP,SRPE) |

Specification | DN50 - DN600mm |

Pressure | PN10,PN16,PN20,PN25,PN30,PN35,PN40 |

Raw Material | 100% Virgin Material PE100 and steel wire |

Standards | ISO4437,CJ/T123-2016,GB/T 17219 EN1555, AS/NZS4130, GOST18599, ASTM F714,CJ/T123-2016 |

Application | water supply, oil transportation, natural gas, mining,methane,, fire fight. |

Connection | Electrofusion Connection,Flange Connection |

Color | Black or Customized |

Product Series

Standard Type: For general pressure applications.

Reinforced Type: Higher pressure tolerance (up to 4.0MPa).

High-Temperature Type: Resists fluids up to 80°C (short-term 100°C).

SRPE Pipe Features

Ultra-high strength and superior ring stiffness

The steel wire mesh skeleton in the middle of the pipe is firmly bonded to the inner and outer layers of HDPE with high-performance adhesive resin, forming a composite structure similar to reinforced concrete. The steel skeleton bears the main mechanical load, especially tensile stress and circumferential stress. This allows the pipe to withstand extremely high internal working pressure and has excellent resistance to external loads and ground settlement. Its ring stiffness is much higher than that of pure plastic pipes, making it suitable for harsh conditions such as ultra-high pressure, large diameter, and deep overburden, without the need for additional concrete encapsulation protection.

Superior Corrosion Resistance and Long Service Life

The steel skeleton is completely encased in a high-density polyethylene (HDPE) layer, completely isolating it from the external environment (soil, groundwater, chemical media) and the internal transported media, fundamentally eliminating electrochemical and chemical corrosion of the steel. HDPE material itself possesses excellent resistance to acids, alkalis, salts, and various chemicals. This dual protection allows the pipeline to be designed for a service life exceeding 50 years, far surpassing traditional steel pipes, and requires virtually no maintenance throughout its entire lifespan, significantly reducing operation and maintenance costs.

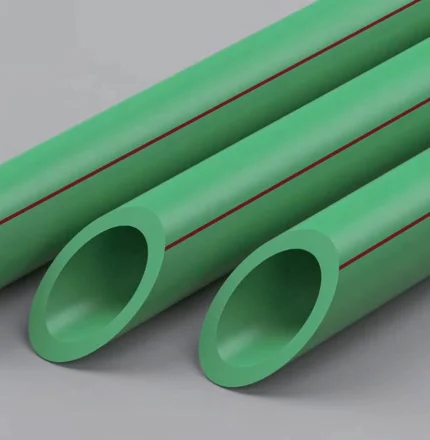

Excellent temperature resistance

The high-temperature resistant model can operate stably at temperatures of 80℃ or even higher for extended periods, broadening its applications in hot and warm water, chemical media transportation, and thermal fields.

Excellent pressure resistance, impact resistance, and toughness

The steel skeleton provides strong pressure resistance, while HDPE gives the pipe good toughness. Even in low-temperature environments (such as -40℃), the pipe maintains excellent impact resistance and will not burst like brittle materials, making it particularly suitable for geologically unstable areas such as earthquake zones, permafrost areas, and mining subsidence areas.

Hygiene and Safety

Food-grade HDPE raw materials meet domestic and international drinking water hygiene standards (such as NSF and KTW), do not scale, and do not breed microorganisms, fully ensuring the purity of the transported medium, making it an ideal pipe material for drinking water.

Economy and Construction Ease

Weighing only 1/4 to 1/8 of steel pipes of the same pressure rating, it greatly reduces the difficulty and cost of transportation, hoisting, and installation. Electrofusion connection is used, utilizing pre-embedded conductive elements to fuse the fittings and pipe material into a single integrated weld. This results in high joint strength, excellent sealing, zero leakage, and fast construction speed, with minimal impact from human and environmental factors.

SRPE Pipe Applications

Energy Transmission Sector

Urban Gas and Municipal Pipelines: As the preferred solution for medium- and high-pressure trunk networks and household access pipes, its corrosion resistance and zero-leakage characteristics greatly enhance the safety and reliability of gas systems.

Long-Distance Oil and Gas Pipelines: Particularly suitable for branch lines, gathering and transmission pipelines, and crossing sections for long-distance high-pressure natural gas transmission. Its comprehensive performance is balanced, and its life-cycle cost advantage is significant.

Industrial Gases: For the transmission of various process gases in chemical plants and power plants, resistant to corrosion from various chemical media.

Water Supply and Water Conservancy Sector

Municipal Water Supply and Drainage Trunk Pipes: High pressure resistance and high sanitary standards, ideal pipe material for urban water supply and greywater reuse.

Large-Scale Water Transmission and Diversion Projects: Used for long-distance pressure water transmission between reservoirs and rivers, with smooth inner walls and high energy efficiency.

High-Efficiency Water-Saving Irrigation in Agriculture: Used as pressure main pipelines in large-scale sprinkler and drip irrigation systems, with good weather resistance and long service life.

Industry and Mining Sector

Petrochemical Industry: For transporting corrosive chemical media, oilfield water injection, polymer injection, etc. Customizable inner layer materials resistant to high temperatures and special chemicals.

Mining Transportation: Used for long-distance, high-pressure transportation of slurry, tailings, and concentrate. Its high abrasion resistance (HDPE layer) and high impact resistance can withstand the abrasion of slurry particles and system pressure fluctuations.

Power Plants: Used in systems for circulating water, demineralized water, and ash/slag transportation, replacing traditional steel pipes and solving corrosion and scaling problems.

Special Environments and Harsh Working Conditions

Highly Corrosive Environments: Its corrosion resistance is irreplaceable in coastal saline-alkali lands, chemically polluted areas, and areas with stray current interference.

High-Risk Areas: Seismically active zones, landslide areas, and permafrost regions; its good toughness and flexibility allow it to adapt to geological deformation within a certain range.

HDPE steel-reinforced composite pipes, through innovative material and structural integration, successfully combine the high strength and high modulus of steel with the corrosion resistance, toughness, and ease of connection of plastics, achieving a balance of rigidity and flexibility. It is not only an upgraded replacement for traditional steel pipes and pure plastic pipes in many high-performance applications, but also a comprehensive solution for conveying systems requiring complex working conditions, long service life, and high safety, playing an increasingly important role in modern infrastructure and industrial construction.

Nominal Diameter | Allowable Deviation of Mean Inner Diameter | Nominal Pressure (PN,Bar) | |||||

PN10 | PN16 | PN20 | PN25 | PN30 | PN40 | ||

Pipe Main Body Thickness and Allowable Deviation (mm) | |||||||

50 | ±1 | - | - | - | 9.0 +1.4 | 10.0 +1.4 | 10.6 +1.6 |

63 | ±1 | - | - | - | 9.0 +1.4 | 10.0 +1.4 | 10.6 +1.6 |

80 | ±1 | - | - | - | 9.0 +1.4 | 10.0 +1.4 | 11.7 +1.8 |

100 | ±1 | - | 9.0 +1.4 | 9.0 +1.4 | 11.7 +1.8 | 11.7 +1.8 | 11.7 +1.8 |

125 | ±1 | - | 10.0 +1.5 | 10.0 +1.5 | 11.8 +1.8 | 12.5 +1.8 | 12.3 +1.8 |

150 | ±1 | 12.0 +1.8 | 12.0 +1.8 | 12.0 +1.8 | 12.0 +2.4 | 13.5 +2.4 | 15.5 +2.6 |

200 | ±1 | 12.0 +1.8 | 12.0 +1.8 | 12.5 +1.9 | 12.5 +1.9 | 14.0 +1.9 | - |

250 | ±0.8 | 12.0 +1.8 | 12.5 +1.9 | 12.5 +1.9 | 13.0 +2.0 | 15.0 +2.0 | - |

300 | ±0.8 | 12.5 +1.9 | 12.5 +1.9 | 12.5 +2.2 | - | - | - |

350 | ±0.8 | 15.0 +2.4 | 15.0 +2.4 | 15.5 +2.5 | - | - | - |

400 | ±0.5 | 15.0 +2.4 | 15.0 +2.4 | 15.5 +2.6 | - | - | - |

450 | ±0.5 | 15.5 +2.6 | 16.0 +2.6 | 16.5 +2.6 | - | - | - |

500 | ±0.5 | 15.5 +2.6 | 16.0 +2.6 | 16.5 +2.6 | - | - | - |

600 | ±0.5 | 19.0 +3.0 | 20.0 +3.0 | - | - | - | |