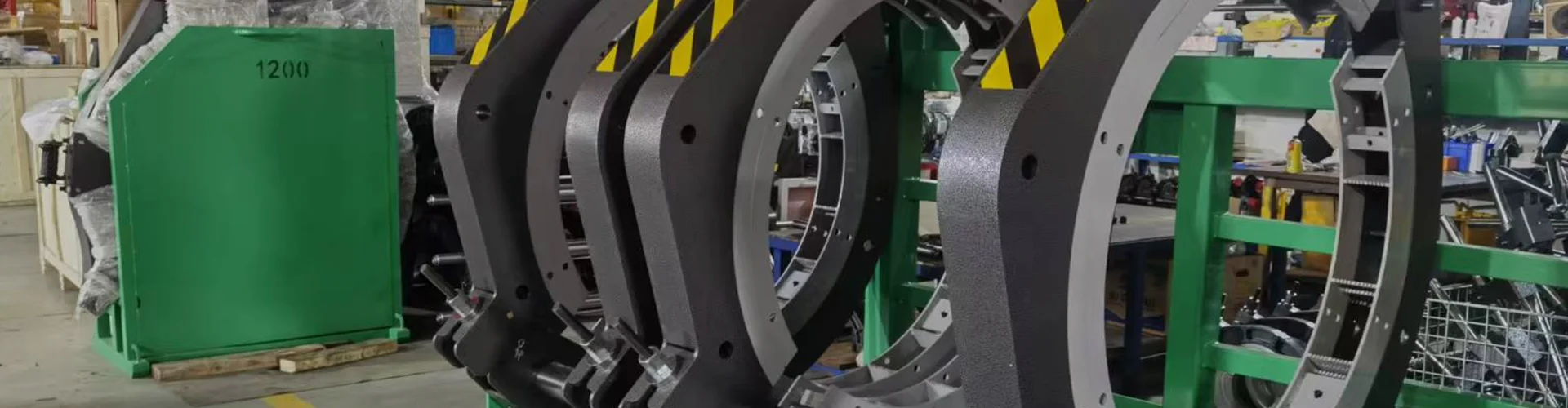

The most popular and reliable welding method for HDPE pipe is Butt fusion welding. Butt fusion welding is thermal jointing. The principle is to heat two pipe ends to designated temperature, and then fuse them together by application of sufficient force. The quality of joints then depends on the quality butt welding machine, proper welding parameters and experience of the welder.

The most popular and reliable welding method for HDPE pipe is Butt fusion welding. Butt fusion welding is thermal jointing. The principle is to heat two pipe ends to designated temperature, and then fuse them together by application of sufficient force. The quality of joints then depends on the quality butt welding machine, proper welding parameters and experience of the welder.

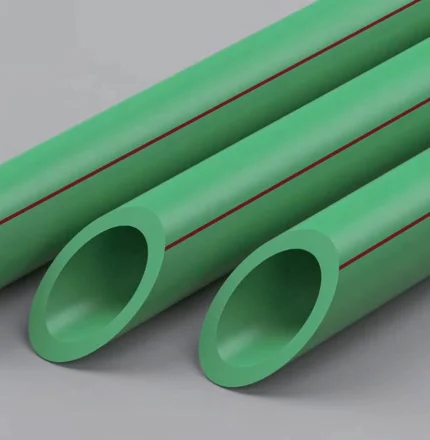

1. Suitable for butt fusion welding of plastic pipes and fittings made of PE, PP, and PVDF in construction site or workshop.

2. Consists of basic frame, heating plate, planing tool, and support (for planing tool & heating plate) and hydraulic unit.

3. Removable PTFE coated heating plate with separate temperature control system.

4. Electric milling cutter with double cutting edge blades.

5. Support for heating plate and planing tool.

6. Low starting pressure ensures reliable welding quality of small pipes.

7. It is made of lightweight and high strength material; simple structure and easy to operate.

8. Hydraulic pump with controls, and quick release hoses. Includes countdown timers for heating and cooling phases.

9. High-accurate and shockproof pressure meter indicates clearer reading.

10. Labor Saving and high efficient crane is available to lift planing tool and heating plate.

Key Features of Butt Welding

Molecular-Level Connection: Polyethylene materials are melted by heating, then diffuse and intertwine under pressure, forming a unified, homogeneous connection upon cooling. The material at the weld joint is identical to the pipe body, achieving true "integral connection."

Permanent Connection: After welding, the connection point becomes an integral part of the piping system, with the same lifespan as the pipe.

Fully Automated Process Control: Modern welding machines use microprocessors to control key parameters such as heating temperature, pressure, and time, eliminating the instability of human operation and ensuring process consistency and repeatability.

No Additional Materials Required: The connection process does not use welding rods, glue, seals, or metal parts; it relies solely on the pipe material itself.

Key Advantages of Butt Welding

Extremely High Connection Strength and Reliability

The tensile strength and pressure resistance of the weld are not lower than, and may even be higher than, the pipe body itself. This is because the welded flange provides reinforcement.

Excellent resistance to internal pressure and external loads, especially suitable for trenchless installations (such as directional drilling) where high tensile stresses are present.

Fundamentally eliminates joint leakage problems, ensuring zero leakage of the transported media (especially water and gas), ensuring safety and environmental protection.

Superior Fluid Performance

The welded joint has a smooth, protrusion-free inner wall that matches the pipe's inner diameter, achieving full-bore coverage.

Significantly reduces fluid resistance, avoids turbulence and scaling, maintains transport efficiency, and provides significant energy savings.

Excellent Long-Term Economic Efficiency

Initial Cost: For large-diameter pipes (typically DN90 and above), butt welding is the most economical connection method, far lower than electrofusion or flange connections of the same diameter.

Operating and Maintenance Costs: Due to the permanent, leak-free connection, the costs of daily inspection, maintenance, and leak repair are greatly reduced. Low life-cycle cost: Matches the design life of the pipeline for more than 50 years, eliminating the need to replace interface components.

Highly efficient and adaptable construction

The welding process is mechanized, with relatively fixed welding times per joint, making it particularly suitable for continuous and rapid construction of long-distance, large-diameter pipelines.

Highly integrated equipment allows operation in various field environments (such as trenches, tunnels, and pits).

It can easily weld pipe sections of different wall thicknesses (but requiring the same SDR grade), offering excellent flexibility.

Excellent Flexibility and Resistance to Stress Cracking

The weld area exhibits similar flexibility to the pipe material, effectively resisting stress caused by foundation settlement and temperature changes.

The properties of polyethylene give the weld excellent resistance to slow crack growth (SCG), ensuring long-term stable performance.