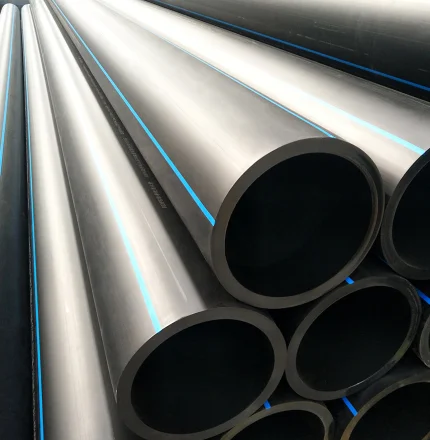

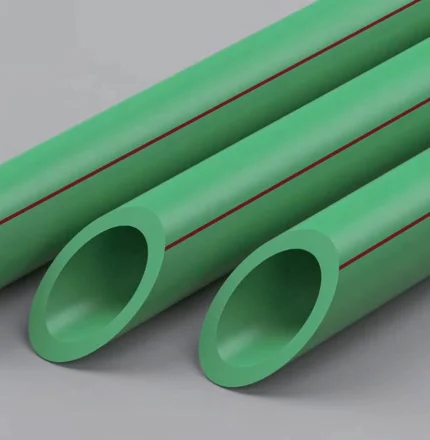

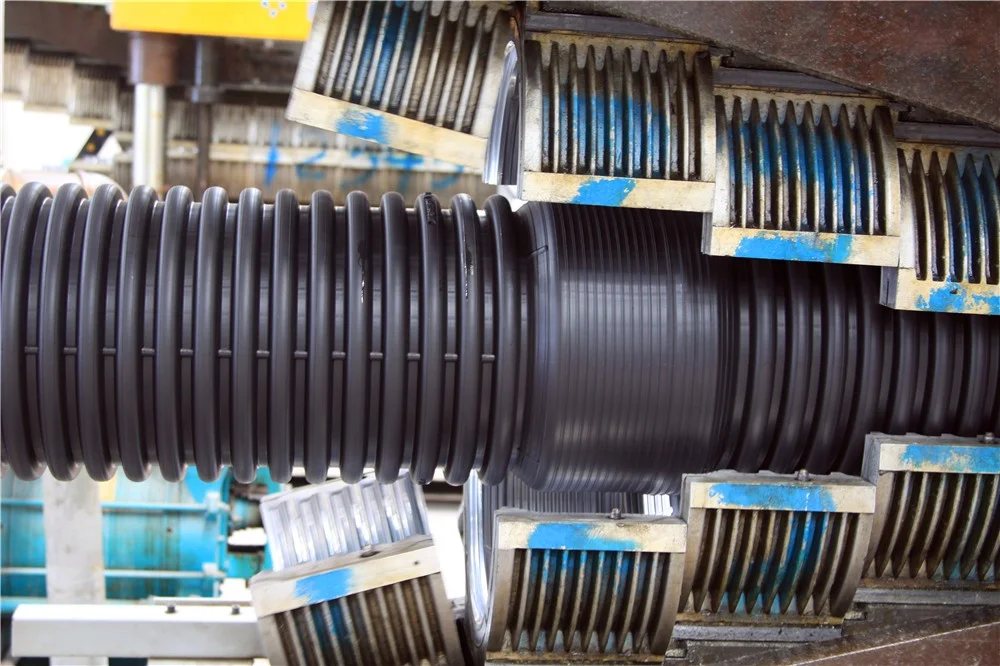

SIFFO HDPE Double Wall Corrugated Pipe is a lightweight, high-strength drainage pipe system manufactured from high-density polyethylene (HDPE) through advanced dual-layer co-extrusion technology. Its unique structure combines a smooth inner wall with a corrugated outer wall, offering excellent fluid transport performance and outstanding ring stiffness.

Parameter | Specification |

Material | High-Density Polyethylene (HDPE) |

Ring Stiffness | SN4, SN8, SN12.5, SN16 |

Diameter Range | DN200-DN1000mm |

Standard | ISO 9969,EN 13476,GB/T 19472.1-2004,ASTM F2306 |

Length | 6m/piece (standard), customizable |

Operating Temperature | -60℃ to +60℃ |

Jointing Methods | Rubber ring socket joint, butt fusion |

Color | Black (standard), customizable |

Impact Resistance | ≥10kJ/m² |

Service Life | ≥50 years |

SIFFO HDPE Double Wall Corrugated Pipe Features

High Ring Stiffness and Compression Resistance: The corrugated structure of the outer wall significantly enhances the ring stiffness of the pipe, enabling it to withstand larger external loads and making it suitable for deep burial projects.

Flexibility and Impact Resistance: HDPE material has good toughness, can adapt to uneven foundation settlement, has strong impact resistance, and is not easily broken.

Corrosion Resistance and Aging Resistance: It has excellent resistance to acids, alkalis, soil corrosion, and microbial erosion, with a service life of over 50 years, and requires no anti-corrosion treatment.

Lightweight and Convenient Construction: Weighing only 1/8 of concrete pipes and 1/5 of cast iron pipes, it has high transportation and installation efficiency, reducing construction costs.

Smooth Inner Wall and Strong Flow Capacity: The inner wall has a low coefficient of friction (Manning coefficient is approximately 0.009), resulting in high drainage efficiency and preventing scale buildup.

Environmentally Friendly and Good Sealing: The socket connection provides strong joint sealing, preventing sewage leakage and soil contamination; the material is recyclable.

Product Advantages

Easy Installation: Uses socket connection or thermal fusion jointing, with installation speed 3-5 times faster than traditional pipes.

Lower Total Cost: Although unit price is slightly higher, savings in transportation, installation and maintenance reduce lifecycle costs by over 30%.

Excellent Adaptability: Wide working temperature range (-60℃ to +60℃), suitable for various climatic and geological conditions.

Superior Hydraulic Performance: Low friction coefficient (Manning's n=0.009), providing 30% greater flow capacity than concrete pipes of same diameter.

Low Maintenance: No regular anti-corrosion treatment needed, with minimal daily maintenance costs.

SIFFO HDPE Double Wall Corrugated Pipe Application Scenarios

Municipal Drainage and Sewage Systems: Urban stormwater and sewage pipe networks;Road drainage and culvert engineering.

Agricultural Irrigation and Water Conservancy: Agricultural drainage pipes and water-saving irrigation channels.

Industrial and Mining Engineering: Mine drainage and ventilation ducts;Factory wastewater discharge pipes.

Power and Telecommunications Cable Protection: Underground cable and fiber optic cable sheathing to prevent mechanical damage and corrosion.

Transportation and Building Engineering: Drainage systems for highways and railways;Underground drainage pipe networks in residential communities.

Ecological and Environmental Protection Engineering: River management and wetland drainage;Leachate collection pipes for landfills.

Quality Assurance

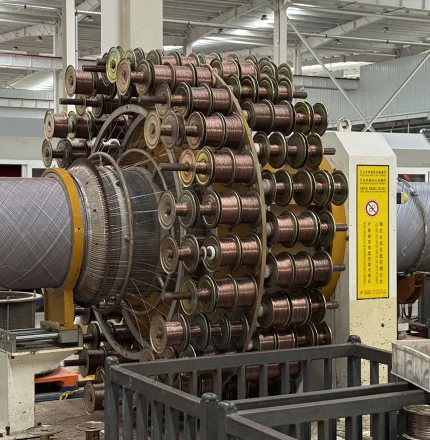

SIFFO Company holds ISO 9001 Quality Management System certification. All HDPE double wall corrugated pipes undergo rigorous testing by the National Chemical Building Materials Testing Center and come with a 10-year quality guarantee. Our fully automated production lines and online monitoring systems ensure every meter of pipe meets the highest quality standards.

Why Choose SIFFO HDPE Double Wall Corrugated Pipes?

Advanced Manufacturing: State-of-the-art production facilities with strict quality control at every stage

Custom Solutions: Wide range of sizes and specifications to meet diverse project requirements

Technical Support: Professional engineering team provides comprehensive technical consultation

Global Experience: Products successfully used in projects across 30+ countries

Sustainable Development: Commitment to environmentally responsible production practices

Nominal Inside Dia.(mm) | Min Average Inside Dia.(mm) | Min Outside Thickness min(mm) | Min Inside Thickness min(mm) | Connection Length(mm) |

200 | 195 | 1.1 | 1.5 | 54 |

300 | 294 | 1.7 | 2 | 64 |

400 | 392 | 2.3 | 2.5 | 74 |

500 | 490 | 3 | 3 | 85 |

600 | 588 | 3.5 | 3.5 | 96 |

800 | 785 | 4.5 | 4.5 | 118 |

1000 | 985 | 5.0 | 5.0 | 140 |