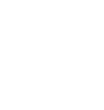

The HDPE Electrofusion Reducing Tee is a specialized polyethylene pipe fitting designed to create branch connections between pipes of different diameters within PE piping systems. Manufactured from premium PE100 resin, this electrofusion reducing tee enables smooth hydraulic transitions while maintaining structural integrity and leak-proof performance across water supply, gas distribution, and industrial applications.

Unlike standard equal tees, our reducing tee eliminates the need for additional reducer fittings, streamlining installation and reducing potential failure points in critical infrastructure networks.

The HDPE Electrofusion Reducing Tee Fitting is designed to create a reliable branch connection in HDPE pipeline systems where one or more outlet diameters differ from the main pipe size. Manufactured from premium PE100 high-density polyethylene, this fitting is equipped with embedded electrofusion heating coils to ensure uniform heat distribution and strong fusion joints.

During the electrofusion welding process, the integrated resistance wires melt both the fitting and pipe surfaces simultaneously, forming a fully homogeneous, leak-proof, and pressure-resistant joint. This guarantees long-term pipeline integrity even in demanding operating environments.

With excellent resistance to corrosion, chemicals, environmental stress, and aging, HDPE electrofusion reducing tees are widely used in modern pipeline systems that require flexible size transitions and high performance.

HDPE Electrofusion Reducing Tee Fitting Features

Made from high-quality PE100 material for superior strength

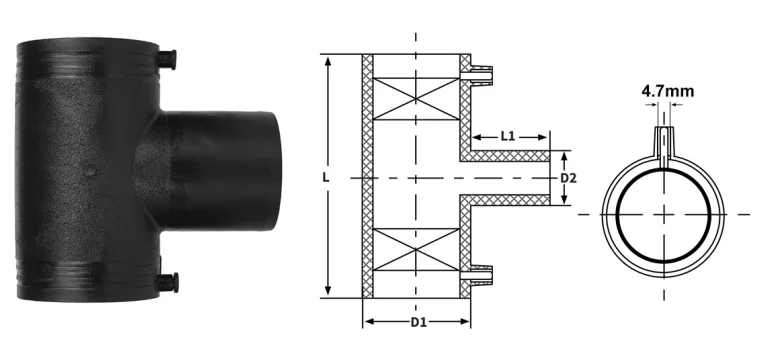

Integrated electrofusion heating wires for consistent welding quality

Secure branch connection with diameter reduction

Leak-proof and high pressure resistant performance

Excellent corrosion, chemical, and UV resistance

Smooth internal surface to minimize flow loss

HDPE Electrofusion Reducing Tee Fitting Applications

Municipal water supply and distribution pipelines

Natural gas and gas transmission networks

Agricultural irrigation systems

Industrial fluid and chemical transportation

Infrastructure and utility engineering projects

HDPE Electrofusion Reducing Tee Fitting Installation

Pre-Installation Requirements

Pipe Preparation: Cut pipe ends squarely using PE pipe cutters

Surface Treatment: Remove oxidation layer with approved scraper tools

Cleaning: Use isopropyl alcohol wipes on pipe and fitting sockets

Marking: Clearly indicate insertion depth on pipe surface

Alignment: Ensure pipe and fitting are coaxial before fusion

Electrofusion Process

Connect fitting to processor using barcode-automated parameter setting

Verify resistance readings match factory specifications

Initiate fusion cycle and monitor temperature indicators

Maintain clamping pressure throughout heating and cooling phases

Allow complete cooling before pressure testing (typically 8-12 minutes for DN110)

Post-Installation Verification

Visual inspection of fusion bead formation

Conduct hydrostatic pressure test per EN 1555/ISO 4427

Document fusion parameters for asset management

SDR11 | ||||

规格 SPECIFICATION | 尺寸 SIZE (mm) | |||

D1 (mm) | D2 (mm) | L1 (mm) | T | |

T50-40 | 62 | 40.3 | 60 | 145 |

T63-40 | 77 | 40.3 | 70 | 165 |

T63-50 | 77 | 50.3 | 70 | 165 |

T75-50 | 90 | 50.3 | 75 | 180 |

T75-63 | 90 | 63.3 | 70 | 180 |

T90-50 | 107 | 50.3 | 75 | 200 |

T90-63 | 107 | 63.3 | 75 | 200 |

T90-75 | 107 | 75.3 | 80 | 200 |

T110-32 | 135 | 32.3 | 80 | 205 |

T110-40 | 135 | 40.3 | 80 | 205 |

T110-50 | 135 | 50.3 | 80 | 205 |

T110-63 | 135 | 63.3 | 80 | 205 |

T110-75 | 135 | 75.3 | 80 | 205 |

T110-90 | 135 | 90.3 | 85 | 205 |

T125-110 | 150 | 110.3 | 90 | 250 |

T160-50 | 190 | 50.3 | 80 | 255 |

T160-63 | 190 | 63.3 | 80 | 255 |

T160-75 | 190 | 75.3 | 80 | 255 |

T160-90 | 190 | 90.3 | 105 | 255 |

T160-110 | 190 | 110.3 | 105 | 255 |

T200-50 | 237 | 50.3 | 80 | 280 |

T200-63 | 237 | 63.3 | 80 | 280 |

T200-75 | 237 | 75.3 | 80 | 280 |

T200-90 | 237 | 90.3 | 80 | 280 |

T200-110 | 237 | 110.3 | 105 | 280 |

T200-160 | 237 | 160.3 | 120 | 355 |

T225-50 | 267 | 50.3 | 80 | 335 |

T225-63 | 267 | 63.3 | 85 | 335 |

T225-75 | 267 | 75.3 | 85 | 335 |

T225-90 | 267 | 90.3 | 90 | 335 |

T225-110 | 267 | 110.3 | 105 | 335 |

T225-160 | 267 | 160.3 | 115 | 335 |

T225-200 | 267 | 200.3 | 120 | 385 |

T250-50 | 297 | 50.3 | 80 | 300 |

T250-63 | 297 | 63.3 | 80 | 300 |

T250-75 | 297 | 75.3 | 80 | 300 |

T250-90 | 297 | 90.3 | 85 | 300 |

T250-110 | 297 | 110.3 | 105 | 300 |

T250-160 | 297 | 160.3 | 120 | 370 |

T250-200 | 297 | 200.3 | 130 | 420 |

T315-50 | 373 | 50.3 | 95 | 410 |

T315-63 | 373 | 63.3 | 95 | 410 |

T315-75 | 373 | 75.3 | 95 | 410 |

T315-90 | 373 | 90.3 | 95 | 410 |

T315-110 | 373 | 110.3 | 110 | 410 |

T315-160 | 373 | 160.3 | 130 | 410 |

T315-200 | 373 | 200.3 | 130 | 410 |

T315-250 | 373 | 250.3 | 150 | 410 |

T355-110 | 422 | 110.0 | 105 | 460 |

T355-160 | 422 | 160.0 | 125 | 460 |

T355-200 | 422 | 200.0 | 125 | 460 |

T355-250 | 422 | 250.0 | 140 | 460 |

T355-315 | 422 | 315.0 | 140 | 565 |

T400-110 | 473 | 110.0 | 105 | 490 |

T400-160 | 473 | 160.0 | 130 | 490 |

T400-200 | 473 | 200.0 | 130 | 490 |

T400-250 | 473 | 250.0 | 140 | 490 |

T400-315 | 473 | 315.0 | 145 | 615 |

T450-110 | 526 | 110.0 | 130 | 700 |

T450-160 | 526 | 160.0 | 145 | 700 |

T450-200 | 526 | 200.0 | 145 | 700 |

T450-250 | 526 | 250.0 | 160 | 700 |

T450-315 | 526 | 315.0 | 160 | 700 |

T450-400 | 526 | 400.0 | 160 | 700 |

T500-110 | 590 | 110.0 | 115 | 545 |

T500-160 | 590 | 160.0 | 130 | 545 |

T500-200 | 590 | 200.0 | 130 | 545 |

T500-250 | 590 | 250.0 | 145 | 545 |

T500-315 | 590 | 315.0 | 145 | 730 |

T500-400 | 590 | 400.0 | 160 | 730 |

T630-110 | 740 | 110.0 | 115 | 700 |

T630-160 | 740 | 160.0 | 115 | 700 |

T630-200 | 740 | 200.0 | 120 | 700 |

T630-250 | 740 | 250.0 | 135 | 700 |

T630-315 | 740 | 315.0 | 150 | 700 |

SDR17 | ||||

规格 SPECIFICATION | 尺寸 SIZE (mm) | |||

D1 (mm) | D2 (mm) | L1 (mm) | T | |

T315-50 | 352 | 50.3 | 95 | 410 |

T315-63 | 352 | 63.3 | 95 | 410 |

T315-75 | 352 | 75.3 | 95 | 410 |

T315-90 | 352 | 90.3 | 95 | 410 |

T315-110 | 352 | 110.3 | 110 | 410 |

T315-160 | 352 | 160.3 | 130 | 410 |

T315-200 | 352 | 200.3 | 130 | 410 |

T315-250 | 352 | 250.3 | 150 | 410 |

T355-110 | 397 | 110 | 105 | 460 |

T355-160 | 397 | 160 | 125 | 460 |

T355-200 | 397 | 200 | 125 | 460 |

T355-250 | 397 | 250 | 140 | 460 |

T355-315 | 397 | 315 | 140 | 565 |

T400-110 | 447 | 110 | 105 | 490 |

T400-160 | 447 | 160 | 130 | 490 |

T400-200 | 447 | 200 | 130 | 490 |

T400-250 | 447 | 250 | 140 | 490 |

T400-315 | 447 | 315 | 145 | 615 |

T500-110 | 563 | 110 | 115 | 500 |

T500-160 | 563 | 160 | 130 | 500 |

T500-200 | 563 | 200 | 130 | 500 |

T500-250 | 563 | 250 | 145 | 500 |

T500-315 | 563 | 315 | 145 | 730 |

T500-400 | 563 | 400 | 160 | 730 |

T630-110 | 700 | 110 | 115 | 700 |

T630-160 | 700 | 160 | 115 | 700 |

T630-200 | 700 | 200 | 120 | 700 |

T630-250 | 700 | 250 | 135 | 700 |

T630-315 | 700 | 315 | 150 | 700 |