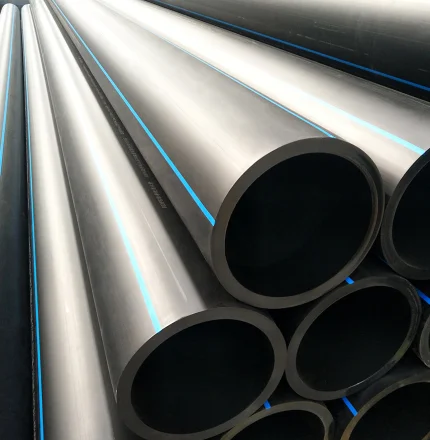

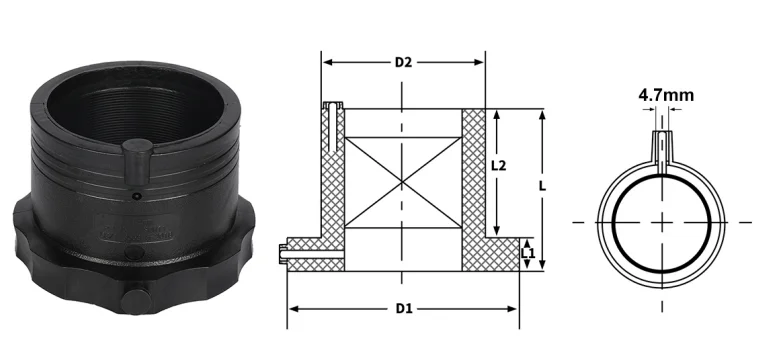

SIFFO's HDPE Electrofusion Stub End, also known as Flange Root or Flange Adapter, is a precision-engineered polyethylene pipe fitting designed to create reliable flange connections in high-density polyethylene (HDPE) piping systems. Manufactured from 100% virgin PE100 resin, this fitting combines the strength of butt fusion welding with the versatility of flanged assembly, making it the preferred choice for water treatment plants, gas distribution networks, mining operations, and chemical processing facilities.

HDPE Electrofusion Stub End Engineering Benefits:

✓ Dual Connection Technology – Integrates seamless electrofusion welding on the pipe side with standardized flange bolting on the equipment side, enabling easy demounting for valve replacement or system maintenance

✓ Superior Chemical Resistance – PE100 material provides exceptional corrosion resistance against acids, alkalis, and electrolytic environments, eliminating the need for cathodic protection

✓ Leak-Proof Integrity – Precision-machined flange face with serrated finish ensures perfect gasket seating and zero leakage under rated pressure conditions

✓ Installation Efficiency – Pre-fabricated design reduces field welding time by 60% compared to traditional fabricated stub ends; compatible with all ISO standard flange drilling patterns (EN 1092-1, ANSI B16.5, AS 2129)

✓ Long Service Life – 50+ years design life with excellent stress cracking resistance (ESCR) and UV stabilization for outdoor applications

HDPE Electrofusion Stub End Primary Applications

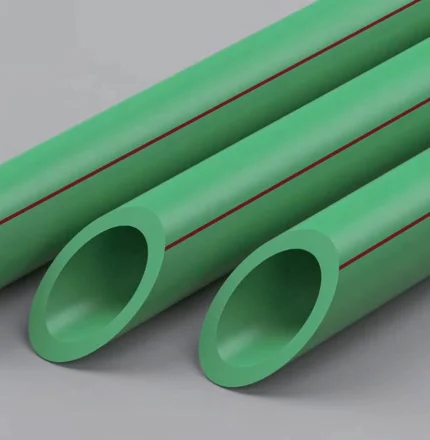

Municipal Water Supply – Clean water transmission mains and distribution networks

Natural Gas Distribution – Medium and low-pressure gas pipeline systems (EN 1555-2 compliant)

Industrial Process Piping – Chemical plants, pharmaceutical facilities, food processing

Mining Slurry Transport – Abrasive media handling with high wear resistance

Landfill Leachate Collection – Environmental protection and waste management systems

Marine Outfalls – Subsea pipeline connections with cathodic disbonding resistance

Why Choose Our HDPE Electrofusion Stub Ends?

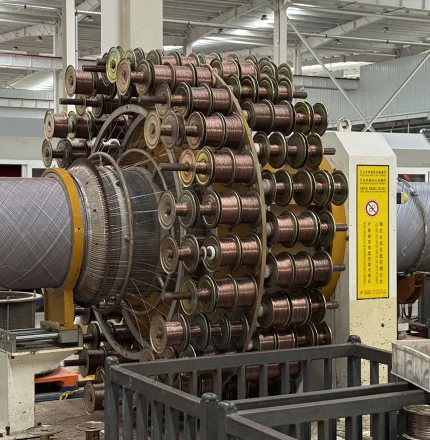

As a leading manufacturer with 20+ years of polyethylene piping solutions experience, we deliver consistent wall thickness, accurate flange face perpendicularity (±0.5mm/m), and complete traceability from raw material to finished product. Our in-house electrofusion testing laboratory ensures every batch meets fusion integrity standards before shipment.

Customization Services: Non-standard flange drilling, special gasket surfaces (RTJ, FF, RF), color coding for utility identification, and integrated backing ring packages available.

SDR11 | |||||

规格SPECIFICATION | 尺寸SIZE (mm) | ||||

D1 | D2 | L1 | L2 | L | |

FL50 | 60 | 82 | 20 | 55 | 75 |

FL63 | 76 | 90 | 20 | 55 | 75 |

FL75 | 89 | 120 | 20 | 55 | 75 |

FL90 | 107 | 132 | 25 | 60 | 85 |

FL110 | 134 | 160 | 25 | 80 | 105 |

FL125 | 152 | 175 | 28 | 85 | 113 |

FL140 | 168 | 190 | 25 | 80 | 105 |

FL160 | 192 | 225 | 30 | 90 | 120 |

FL200 | 237 | 275 | 35 | 95 | 130 |

FL225 | 267 | 295 | 35 | 85 | 120 |

FL250 | 297 | 327 | 35 | 115 | 150 |

FL280 | 310 | 375 | 32 | 110 | 150 |

FL315 | 361 | 430 | 40 | 120 | 160 |

FL355 | 404 | 460 | 40 | 105 | 145 |

FL400 | 455 | 510 | 40 | 110 | 150 |

FL500 | 558 | 630 | 60 | 140 | 200 |

SDR17 | |||||

· 规格SPECIFICATION | 尺寸SIZE(mm) | ||||

D1 | D2 | L1 | L2 | L | |

FL315 | 352 | 395 | 40 | 115 | 155 |

FL355 | 395 | 450 | 40 | 105 | 145 |

FL400 | 445 | 505 | 40 | 110 | 150 |

FL450 | 500 | 560 | 50 | 110 | 160 |

FL500 | 555 | 615 | 50 | 130 | 180 |

FL560 | 618 | 670 | 60 | 150 | 200 |

FL630 | 688 | 750 | 60 | 160 | 220 |

FL710 | 760 | 840 | 72 | 195 | 270 |

FL800 | 880 | 940 | 70 | 200 | 270 |