Client Profile

The project is situated within the agricultural heartland of the Kyrgyz Republic, a landlocked nation in Central Asia where agriculture constitutes approximately 20% of GDP and employs over 50% of the labor force . The farm operates in a region characterized by semi-arid climatic conditions and significant topographical variations typical of the Tien Shan mountain foothills, where irrigation infrastructure serves as the critical lifeline for agricultural productivity. The specific implementation site relies heavily on seasonal meltwater from mountain glaciers and snowpack, with declining river flows and increasing climate variability creating urgent pressure for modernization . This location places the farm at the center of national food security concerns, where reliable water access directly determines agricultural viability and rural economic stability.

The farm operates within the broad-acre agricultural sector, focusing on crop cultivation in a continental climate characterized by hot, dry summers with temperatures frequently exceeding 35°C and cold winters plunging below -20°C . Annual precipitation averages less than 400mm in many agricultural zones, with drought periods becoming increasingly frequent due to climate change impacts on the region's cryosphere . This arid and semi-arid climate classification places extraordinary demands on irrigation infrastructure, as evapotranspiration rates frequently exceed precipitation during the critical growing season from May through September. The sector faces mounting pressure from accelerated glacial retreat and increasingly irregular precipitation patterns, prompting the Kyrgyz government to prioritize water-saving irrigation expansion targeting 200,000 hectares by 2030, up from the current 16,000 hectares under modern irrigation systems .

Challenges

Water scarcity in an inland region.

Need for an affordable yet durable irrigation system.

Requirement for efficient water distribution across a large area.

Demand for low-maintenance and long-lasting infrastructure.

The SIFFO Solution

Shandong SIFFO Plastic Technology Co., Ltd. engineered a comprehensive PVC pressure irrigation system tailored to Central Asian agricultural realities:

High-Performance Infrastructure

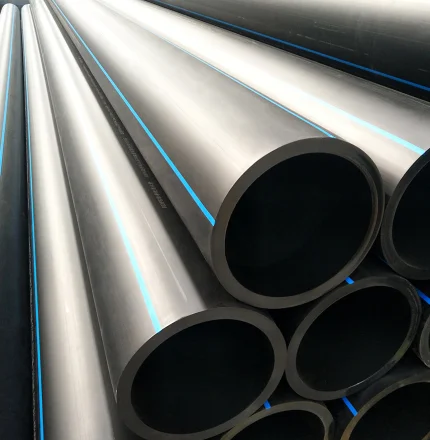

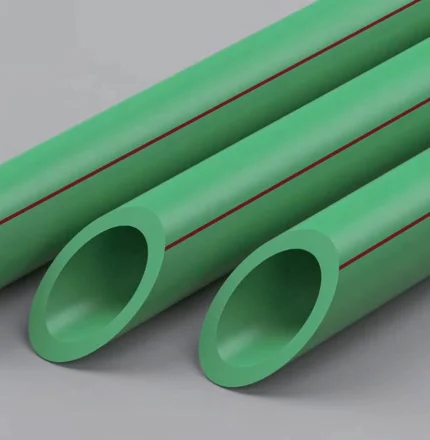

PVC Pressure Pipeline Network: 160mm–200mm PN16 (16-bar) Class pipes providing exceptional structural integrity and surge pressure resistance

Ring-Rubber Joint System: Advanced elastomeric seal connections enabling rapid, tool-free assembly while accommodating thermal expansion and ground movement

Precision Sprinkler Integration: Compatible high-efficiency rotator sprinklers delivering uniform water distribution with <5% evaporation loss

Technical Differentiation

Our technical team specified PN16 pressure ratings significantly exceeding standard PN10 agricultural norms, ensuring system resilience against water hammer effects and topography-induced pressure variations across the farm's undulating terrain.

Economic Value

Total installed cost remained 35% below comparative metal or HDPE alternatives, delivering IRR-positive returns within the first growing season through yield improvements and water cost savings.

Implementation

Engineering & Logistics

SIFFO's project engineers conducted hydraulic modeling to optimize pipe routing across the 100-hectare parcel, minimizing material waste while ensuring full-field coverage. Despite Kyrgyzstan's challenging logistics corridor, our manufacturing facility delivered 12km of customized pipe lengths within 18 days.

SIFFO Engineers Dispatched to Kyrgyzstan Project Site

ecognizing the critical importance of proper installation for system longevity and performance, SIFFO provided comprehensive on-site technical supervision throughout the construction phase, with experienced engineers deployed to the Kyrgyzstan farm to oversee critical installation procedures . These technical experts provided real-time guidance on trench excavation standards (minimum 1.0 meter depth for frost protection, 0.3 meter sand bedding for pipe protection), pipe handling procedures (avoiding impact damage during unloading and stringing), and joint assembly techniques (proper lubrication and insertion depths for rubber ring connections) . The presence of SIFFO engineers ensured that installation practices conformed to international standards (ISO 4422 for PVC pipe installation) while adapting to local construction capabilities and equipment limitations.

Practical Instruction for Local Farm Technicians

A critical component of SIFFO's service delivery involved comprehensive training programs for the farm's technical staff and maintenance personnel, transferring knowledge necessary for independent system operation and basic troubleshooting . Training modules covered pipe system maintenance (leak detection, joint inspection, pressure testing procedures), sprinkler adjustment and replacement, winterization protocols (draining systems to prevent freeze damage during Kyrgyzstan's harsh winters), and basic hydraulic troubleshooting (identifying blockages, pressure irregularities, or pump issues) . The hands-on approach ensured that local technicians developed practical competencies in rubber ring joint assembly, valve operation, and filtration system maintenance, reducing long-term dependency on external technical support.

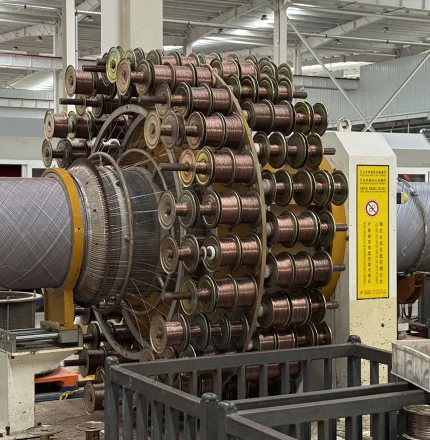

Supervision of Rubber Ring Connection Procedures and Pressure Testing

SIFFO engineers implemented rigorous quality control protocols during the installation phase, supervising critical connection procedures to ensure that rubber ring joints were properly lubricated, pipes fully inserted to reference marks, and joint alignments maintained within allowable tolerances (maximum 2 degrees angular deflection) . Following installation completion, SIFFO supervised hydrostatic pressure testing procedures in accordance with international standards, involving gradual pressurization to 1.5 times the working pressure (approximately 9-10 bar for this PN16 system) and holding for minimum periods to verify joint integrity and absence of leakage . This quality assurance process identified and rectified several installation issues (improper gasket seating, insufficient insertion depths) before system commissioning.

Results

Conservation Achievement: 50% Reduction in Water Consumption vs. Flood Irrigation

The implemented system achieved the targeted approximately 50% reduction in water consumption compared to the farm's previous flood irrigation practices, representing a transformation from water-intensive surface application to precision pressurized delivery . This conservation resulted from the combination of pressurized distribution eliminating seepage losses (previously 20-30% in unlined earthen canals), reduction of application losses through controlled sprinkler precipitation rates matching soil infiltration capacities (eliminating the runoff common in flood systems), and elimination of deep percolation losses through precise application depth control . For the 1,500 mu farm, this 50% reduction translates to annual water savings of 250,000-400,000 cubic meters, assuming typical irrigation requirements of 5,000-8,000 m³/ha/season .

Operational Cost Reduction: 40% Decrease in Annual Irrigation Expenses

The operational cost structure of the SIFFO irrigation system offers significant advantages over traditional irrigation methods, with annual operating expenses projected to decrease by approximately 40% compared to the farm's previous flood irrigation practices . These reductions stem primarily from decreased energy consumption (smaller pumps operating for shorter durations due to higher application efficiency), reduced labor requirements (one operator managing 1,500 mu via automated controls versus multiple workers managing flood irrigation), and elimination of the land preparation costs associated with maintaining flood irrigation furrows and leveling requirements .

Yield Enhancement: 30% Increase in Crop Production Through Optimized Hydration

The improved water management capabilities of the SIFFO irrigation system contributed to documented yield enhancements of approximately 30% compared to pre-installation flood irrigation baselines . This yield improvement resulted from the ability to maintain optimal soil moisture levels throughout the growing season, eliminating both water stress periods that limit plant growth and waterlogging conditions that cause root hypoxia and nutrient leaching. The uniformity of water distribution achieved through pressure-regulated sprinklers (Christiansen Uniformity Coefficient >85%) ensures that all plants within the 1,500 mu area receive identical water volumes, producing uniform crop maturity that facilitates mechanized harvesting .

Projected Lifespan: 15+ Years Operational Durability in Central Asian Climate

Based on SIFFO's material specifications and the performance characteristics of PVC-U materials, the irrigation system is projected to provide operational service exceeding 15 years under the Central Asian climate conditions . This exceptional longevity derives from the material's inherent resistance to corrosion, chemical degradation, and biological attack, combined with UV-stabilized formulations that prevent photodegradation from intense high-altitude sun exposure. The PN16 pressure class provides substantial safety margins against fatigue failure and creep rupture over extended service periods .

Client Testimonial

"We were hesitant about the installation complexity for such a large area, but Shandong SIFFO's team stayed with us through the entire setup. The rubber joint system proved incredibly forgiving on our uneven ground, and the PN16 pressure rating gives us confidence during peak pumping periods. This system has fundamentally changed our water security."

— Farm Operations Manager, Chuy Valley Agricultural Cooperative

About Shandong SIFFO Plastic Technology Co., Ltd.

SIFFO specializes in manufacturing high-quality PVC piping systems for agricultural, industrial, and civil applications. With a focus on innovation, reliability, and customer support, we provide tailored solutions to clients worldwide. Our products are designed to perform in challenging environments, delivering long-term value and efficiency.