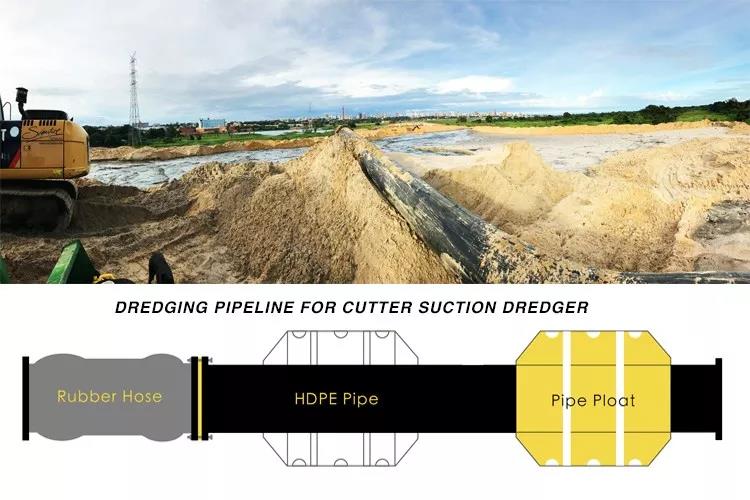

HDPE Dredging Pipe

HDPE dredging pipe is a professional engineering pipe made of high-density polyethylene (HDPE) material, designed for dredging engineering scenarios. This pipe uses the excellent corrosion resistance, high toughness and wear resistance of HDPE material to efficiently transport mixed media containing silt and stones. Its unique flexibility can adapt to complex geological conditions, such as river bends or tidal areas, and can be quickly installed with hot-melt welding technology, making it an ideal choice to replace traditional metal pipes in modern water conservancy and port construction.

HDPE dredging pipes are very different from traditional pipes

Material properties:

HDPE dredging pipe: Made of high-density polyethylene, it has the characteristics of corrosion resistance, good flexibility and light weight.

Traditional pipes: May be made of metal (such as steel, cast iron) or concrete, with different corrosion resistance and mechanical properties.

Application scenarios:

HDPE dredging pipe: Mainly used in dredging projects, such as river dredging, port construction, etc., because of its flexibility and wear resistance, it is suitable for complex terrain.

Traditional pipes: May be used in a wider range of fields, such as water supply, drainage, oil and gas transportation, etc., and the specific application depends on the material properties.

HDPE pipes can be installed floating on the water surface, adapting to complex waters such as swamps and tidal areas, and metal pipes require heavy equipment for lifting.

Installation and maintenance:

HDPE dredging pipe: Easy to install, can be connected by hot melting or electric melting, and has low maintenance costs.

Traditional pipes: Installation may be more complicated and maintenance costs may be higher, especially metal pipes are susceptible to corrosion.

Cost-effectiveness:

HDPE dredging pipe: Although the initial investment may be high, the long-term maintenance cost is low and the life is long.

Traditional pipelines: Initial investment may be lower, but long-term maintenance costs may be higher and lifespan may be shorter.

Environmental adaptability:

HDPE dredging pipelines: Highly adaptable and can be used in complex geological and hydrological conditions.

Traditional pipelines: May be subject to greater restrictions of geological and hydrological conditions.