HDPE Coex White Pipe HDPE Water Supply Pipeline

HDPE Coex White Pipe white appearance: provides high recognition, easy construction, installation and maintenance, while reducing heat absorption and lowering the water temperature rise in the pipe.

Multi-layer co-extrusion structure: Through the co-extrusion of different materials, the pipe's anti-ultraviolet, anti-aging, corrosion resistance and other properties can be optimized to extend its service life.

Environmental protection and hygiene: It meets the drinking water hygiene standards, is non-toxic and odorless, and is suitable for transporting drinking water.

HDPE Coex White Pipe: The co-extrusion process enhances specific properties (such as UV resistance and aging resistance), and the white appearance improves recognition. It is suitable for scenarios with special requirements on pipe appearance or performance.

Chemical corrosion resistance: Excellent tolerance to chemicals such as acids, alkalis, and salts.

Good flexibility: Can be bent to adapt to complex terrain, reduce the use of joints, and reduce the risk of leakage.

Easy installation: Use hot melt or electric fusion connection, good sealing and high construction efficiency.

Material safety: PE80 or PE100 grade raw materials that meet national standards are used to ensure water quality safety.

High strength and pressure resistance: Able to withstand high working pressure and adapt to different water supply needs.

Long life: Designed service life of more than 50 years, reducing replacement frequency and maintenance costs.

Feature

| Product Name | SIFFO HDPE Water Pipe |

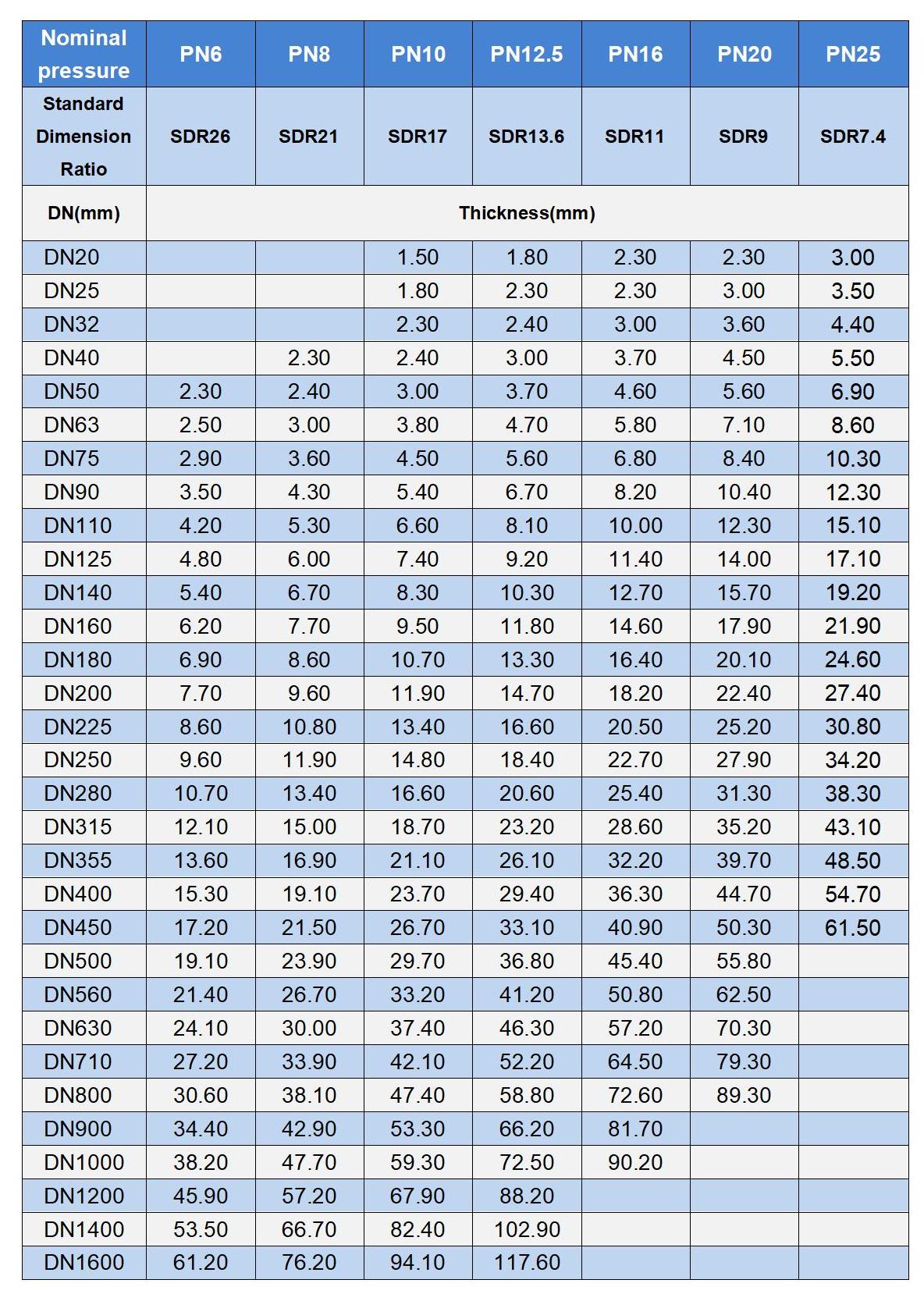

| Specification | DN20 - DN1400mm |

| Pressure | SDR9-PN20, SDR11-PN16, SDR13.6-PN12.5, SDR17-PN10, SDR21-PN8, SDR26-PN6, SDR33-PN5 |

| Raw Material | PE80 PE100 |

| Standards | ISO 4427, AS/NZS 4130, BS EN 12201,DIN 8077 |

| Application | Urban drink water supply |

| Agricultural irrigation. | |

| Sewage discharge. | |

| Landscape garden water supply | |

| Electrical Cable threading. | |

| Connection | Butt fusion Welding, Electrofusion Welding |

| Color | Black or Customized |

HDPE White Co-extruded Pipe Material Properties

1. Physical Properties

Appearance and Structure: HDPE White Co-extruded Pipe is milky white and translucent, with visible light transmittance in a thin cross section, high flexibility, and elongation at break exceeding 350%, which is suitable for installation in complex terrains.

Density and Melting Point: The density is lower than that of water (about 0.94-0.96g/cm³), the melting point range is 132-135°C, and it can be slightly soluble in solvents such as toluene and amyl acetate at high temperatures.

Mechanical Strength: HDPE White Co-extruded Pipe has excellent compression, wear and seismic resistance, can withstand soil settlement and external impact, and is suitable for complex geological conditions such as earthquake zones.

2. Chemical Properties

Corrosion Resistance: HDPE White Co-extruded Pipe is stable to chemical substances such as hydrochloric acid, hydrofluoric acid, and phosphoric acid, but is easily corroded by nitric acid and sulfuric acid, and direct contact should be avoided.

Light Stability: The original material has weak UV resistance and is easily oxidized and degraded under long-term light exposure. Stabilizers such as carbon black need to be added to enhance weather resistance.

3. Thermal performance

High temperature resistance: HDPE White Co-extruded Pipes can withstand high temperatures of 90°C for a short period of time (such as PE-RT modified materials), and is suitable for hot water transportation scenarios.

Low temperature resistance: It remains tough at low temperatures, has excellent impact resistance below freezing point, and prevents freezing cracks.

Material features of HDPE White Co-extruded Pipe

1. Hygienic and safe

Non-toxic and harmless: HDPE White Co-extruded Pipe does not add heavy metal stabilizers during processing, the material is non-toxic, the inner wall is smooth and scale-free, bacteria are prevented from growing, and it meets the sanitation standards for drinking water.

2. Long life

Design life of more than 50 years: HDPE White Co-extruded Pipe can be safely used for more than 50 years under rated temperature and pressure conditions, with low maintenance costs.

3. Convenient construction

Lightweight and easy to install: HDPE White Co-extruded Pipe has low density and is easy to carry. It supports hot melt and electric fusion connection. The interface strength is higher than the main body, eliminating the risk of leakage.

Non-excavation technology: It supports construction methods such as jacking and directional drilling, and is suitable for complex terrain and scenes where excavation is not allowed.

4. Environmental protection

Recyclability: 100% recyclable and reusable, the production process is pollution-free, and it meets the standards of green building materials.

HDPE White Co-extruded Pipe is suitable for

Municipal water supply: main pipes, water distribution pipes, suitable for buried and open-air environments.

Building water supply: hot and cold pipe systems, replacing traditional metal pipes.

Agricultural irrigation: transport irrigation water, adapt to complex terrain and soil conditions.

Industrial field: liquid transport pipelines in chemical, printing and dyeing, pharmaceutical and other industries.

HDPE white water pipe has become an ideal choice for modern water supply systems due to its excellent physical and chemical properties and convenient construction. Its sanitation, safety, long life and environmental protection make it widely used in municipal administration, construction, agriculture and other fields. It is a cost-effective solution to replace traditional metal pipes and PVC pipes.

Application of HDPE white water pipe

Certification